Pyroscan-U

EXTERNAL PYROMETRIC CAMERA FOR COMBUSTION THERMAL MONITORING

Highly Accurate thermal mapping from outside the combustion zone

Pyroscan-U is specifically designed to perform thermal monitoring and mapping of any object inside a kiln, furnace, boiler or reactor, while looking at the area of interest through a standard window, from outside the combustion chamber.

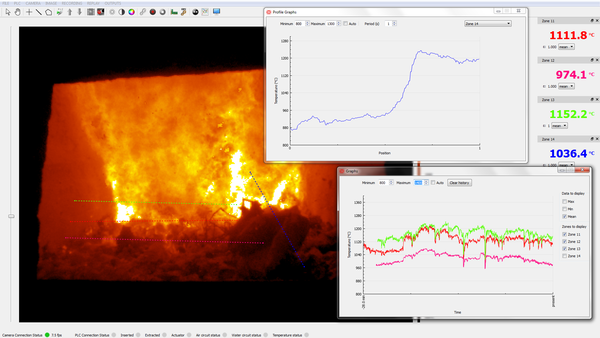

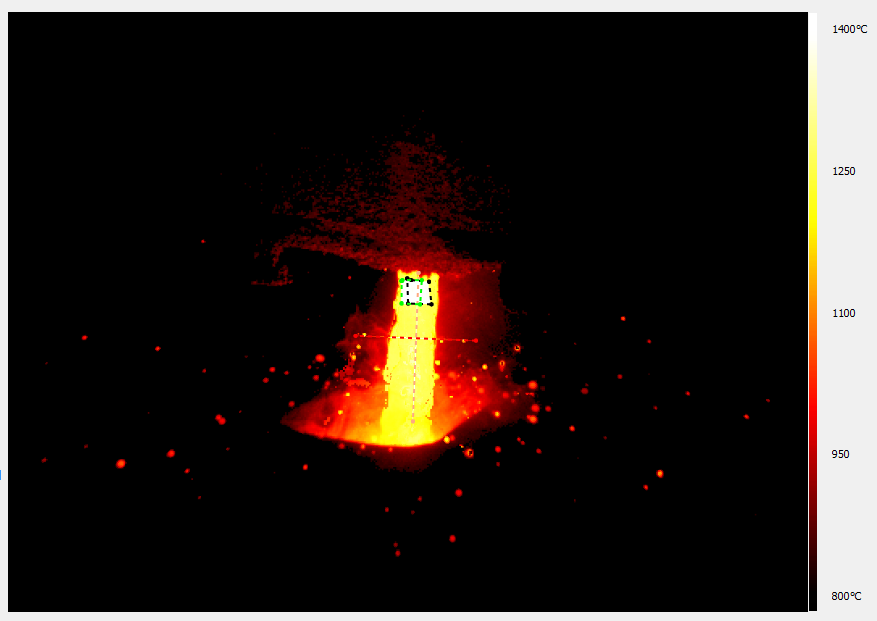

This megapixel pyrometric camera captures both visible and infrared HDR (High Dynamic Range) images of the burning zone. The user-friendly and customizable Pyroscan software, running on a remote computer in the plant control room, displays the high-resolution images for an acute visualization of the combustion stages, and provides accurate temperature measurements in real-time over 1.2 million points within the field of view. The software also includes advanced functionalities, such as anti-dust filtering; real-time statistics on temperature measurements over user-defined free-form areas; multiple ways for setting alarm thresholds, automatic flame front detection, and more, for the highest performance thermal monitoring and process management experience.

3 Key Points

High-performance 1.2 Megapixels external pyrometric camera

Versatile and accurate thermal mapping for the control of waste incineration processes

No external cooling unit required; a zero maintenance and calibration tool

PYROSCAN-U

Essential camera for thermal monitoring in high temperature processes

Pyroscan-U benefits from more than 30 years of expertise, in high-end infrared sensors and thermal image analysis software for industrial thermography applications. It has been developed to reduce the cost of ownership of thermal monitoring systems with the high temperature process fully observed behind a protective window. The system does not require an external cooling unit, which cuts down on maintenance costs. The ruggedized, compact camera requires minimal installation time, and is connected to the control room by a fiber optic cable or by a Gigabit Ethernet connection. Temperature information can be transferred to the Distributed Control System (DCS) of the plant through OPC client or through eight 4-20mA outputs. Thanks to specific algorithms for real-time flame front monitoring, developed through a partnership with a global leader in the waste-to-energy industry, Pyroscan-U is the ideal system for the accurate thermal monitoring in waste incinerators. In addition, since the camera detects any and all changes due to burner or process adjustment, raw meal and fuel composition variations, it is also very well suited for many other extreme environments like: kilns, furnaces, heaters, smelters and boilers.

Pyroscan-U Features

- Accurate thermal measurement over 700 °C to 1800 °C temperature range, with a 1296×966 pixels resolution

- HDR videos in real time (camera dynamic range >120dB)

- Connection to DCS (Distributed Control System) through industry-standard interfaces

- Dedicated software for real-time thermal monitoring:

- Embedded image processing anti-dust filter

- Extensive set of color-coding tables for optimal image legibility

- Definition of an un-limited number of temperature measurement areas (line, free-form polygon or single point)

- Real-time statistics analysis (min, max, mean curves) on selected areas

- Automatic flame front monitoring

- User-defined alarm thresholds (on min., max. or differential temperatures)

- Historical data management – Video and data record/playback functions

- Video export to .avi files

Benefits

- Real-time monitoring of high-temperature processes, using sharp and contrasted visible and thermal images

- The hottest flames and the calcined materials in the darkest areas are visible on the same images, without under-exposed or bloomed zones

- Accurate 24/7 temperature surveillance, flame monitoring and tracking of flame front

- User-friendly and powerful thermal monitoring tool, easily interfacing with plant DCS

- Supports automatic process control and failure detection

- Compact and cost-effective solution, with no maintenance or calibration required

Technical specifications :

Pyroscan-U

Camera

1.2 Megapixels, 1296 x 966 resolution, visible and pyrometric

Field of view

62° (horizontal) x 48° (vertical)

78° (diagonal) or 44° (horizontal) x 33° (vertical)

55° (diagonal) on request