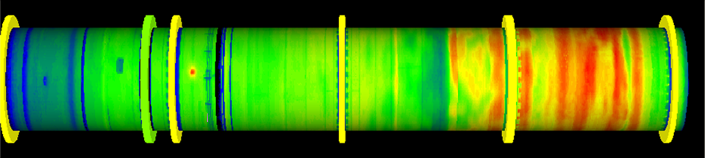

Monitoring the hot spots evolution is the first task that thermal scanners must perform to detect the risk of permanent damage to rotary kilns. HGH Infrared Systems supplies high-performance scanners with the best resolution and sensitivity. The company also provides early warning of the slightest fall of a refractory brick.

In industries using rotary kilns in their manufacturing process, such as the production of cement, lime, refractory materials, alumina and iron ore, early detection of hot spots is essential to avoid production interruption due to falling refractory bricks.

However, for effective, reliable furnace monitoring, you need to choose a high-performance scanner with the best spatial and thermal resolution. The size of the spot at the kiln must be small enough to detect a single falling brick, and the electronic noise of the infrared detector must be as low as possible, so that small temperature variations can be detected.

Download Cases studies:

Each refractory brick is monitored 24×7. With a resolution of less than the size of a brick, Kilnscan will provide early warning of any hot spot formation.

HGH is a electro-optical devices global provider. The company provides wide area surveillance, industrial thermography and electro-optical test solutions.