KILNSCAN

ROTARY KILN INFRARED SCANNER

Rotary kiln shell temperature monitoring

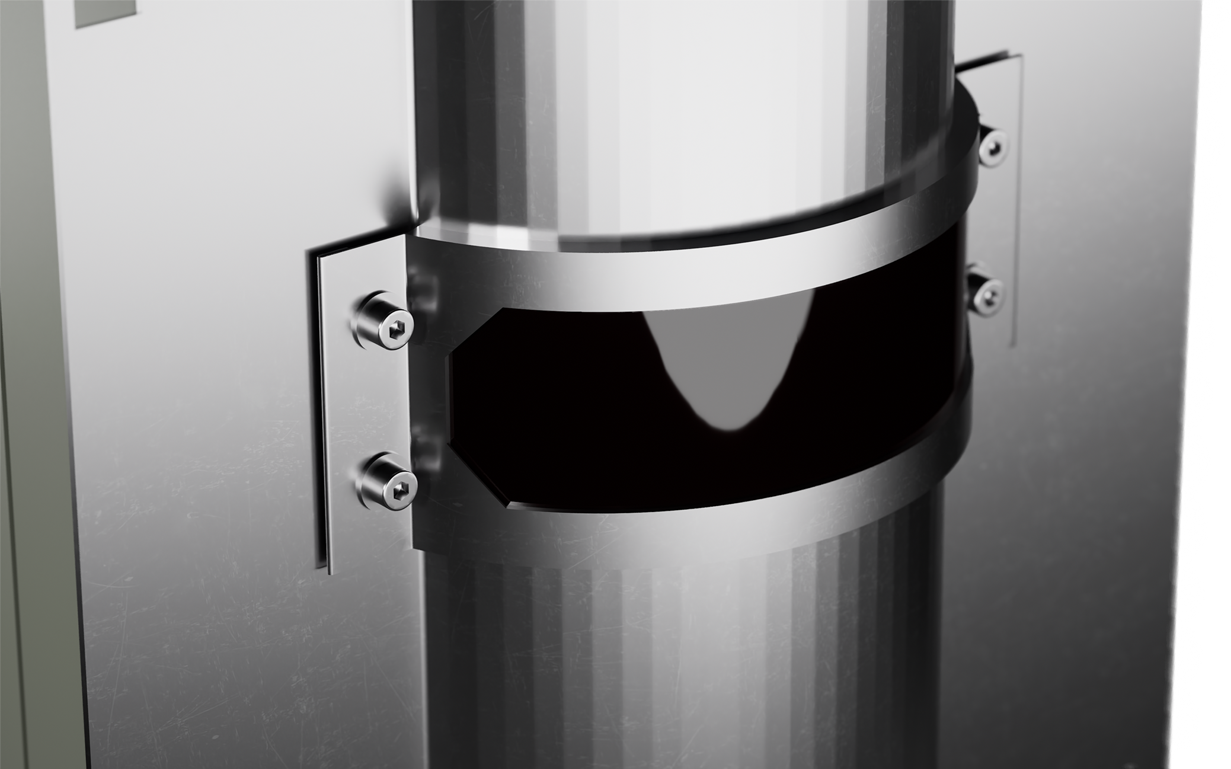

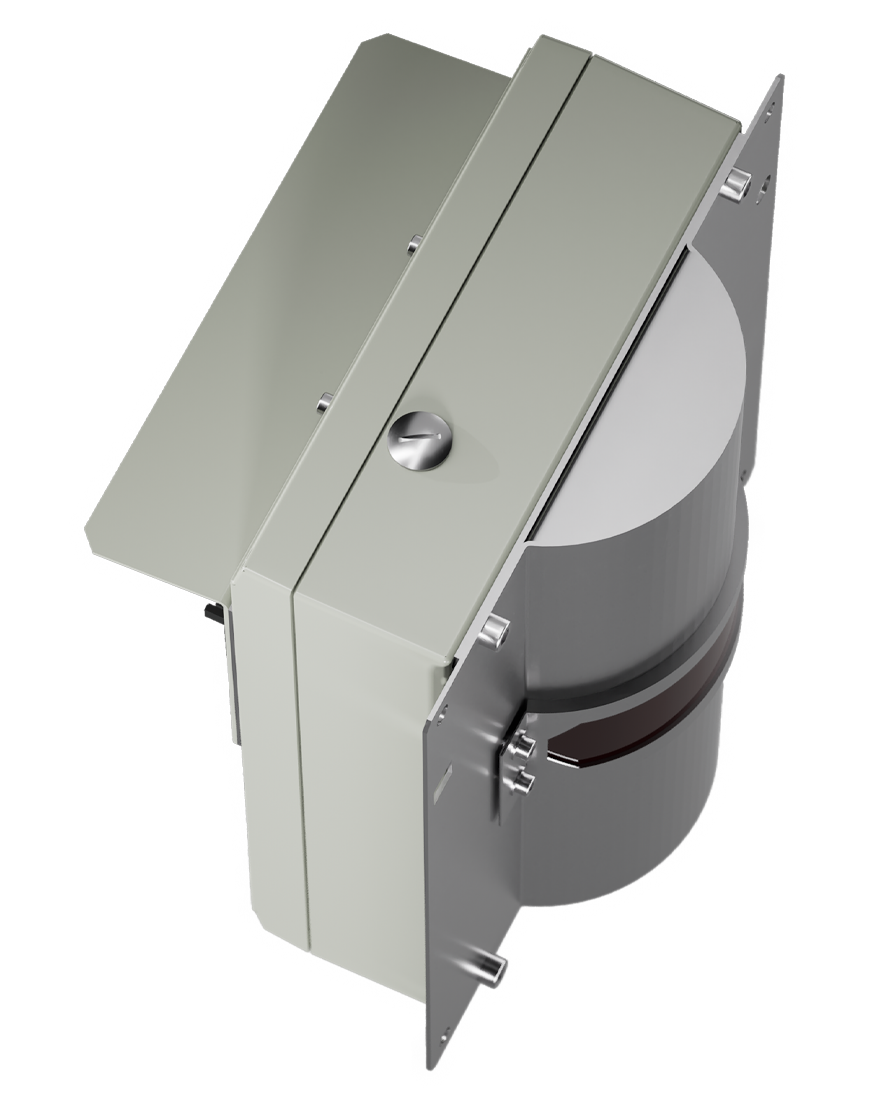

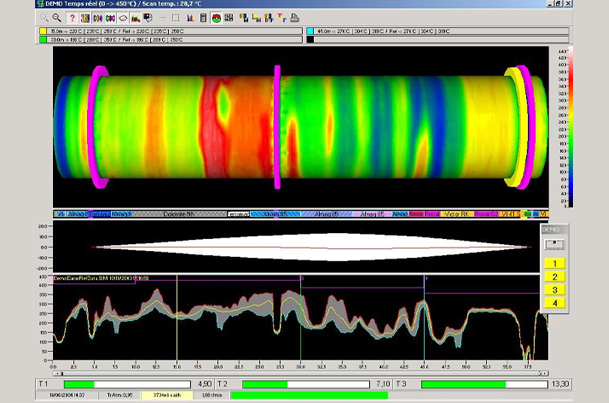

Kilnscan is a high performance thermal scanner dedicated to the real-time, 24/7 temperature monitoring of the kiln shell. It displays the full temperature profile of the kiln and gives early warning of hot spots indicative of refractory failure.

With the highest scan angle of the industry up to 140°, Kilnscan adapts to any kiln configuration: long shell with limited free space around, kilns with multiple shadows generated by posts, etc.

Thanks to advanced features, such as the unique thermal warp calculation and historical data management, Kilnscan provides the operator with the full picture of the rotary kiln to secure a predictive maintenance program.

Kilnscan infrared scanner contributes to optimizing kiln efficiency and availability, increasing production rate, reducing operating costs, improving the burning process and saving energy.

KILNSCAN

MAIN BENEFITS

ACCURATE THERMAL MAPPING

Continuous full temperature map, with a true one-brick resolution

PREVENTING DAMAGE

Hot spots early warning before damage

ENHANCING REFRACTORY LIFESPAN

Monitoring and extension of refractory lifetime

RELIABLE MAINTENANCE SCHEDULING

Reliable preventive maintenance scheduling

VERSATILE SOLUTION

Solution adapted to any requirement (multiple shadows – long kiln – free space limited)

SCANNER DATA INTEGRATION

Scanner data directly linked to Plant Control System

High performance diagnosis system for continuous temperature monitoring of kiln shell

With the best spatial and thermal resolution, Kilnscan monitors each individual refractory brick over the

whole length of the kiln.

It tracks hot spots, tyre slip, rings formation, brick failures, thermal warp and more, to prevent short and longer-term damages.

Kilnscan is a rugged system designed for demanding environments. With more than 1,300 units operating around the world, HGH thermal scanners are used in plants to warn of potential failures and trigger preventive actions.

With the best spatial and thermal resolution, Kilnscan monitors each individual refractory brick over the whole length of the kiln.

It tracks hot spots, tyre slip, rings formation, brick failures, thermal warp and more, to prevent short and longer-term damages.

Kilnscan is a rugged system designed for demanding environments. With more than 1,300 units operating around the world, HGH thermal scanners are used in plants to warn of potential failures and trigger preventive actions.