- Home

- ITH

- Applications

- Rotary Kiln

ROTARY KILN THERMAL MONITORINGFor safer, more efficient cement production

Rotary kiln thermal monitoring for performance, safety, and efficiency

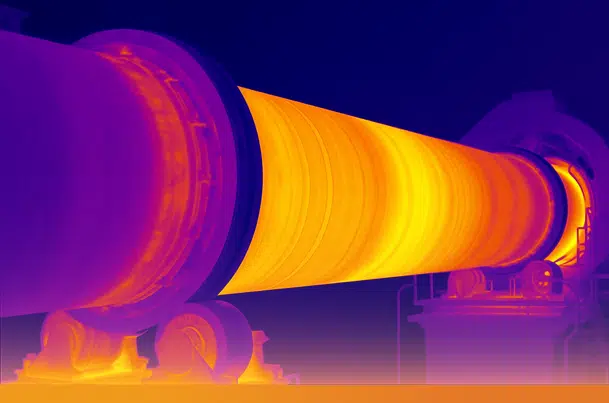

Rotary kilns are at the heart of cement manufacturing, and their performance directly impacts production efficiency, energy consumption, and equipment lifespan. Advanced thermal monitoring systems like KILNSCAN and PYROSCAN provide real-time visibility into both the external and internal conditions of the kiln, helping operators improve control, ensure safety, and extend the lifetime of critical components. Discover how infrared technology is transforming kiln operations through accurate, data-driven decision-making.

Why thermal monitoring is essential in rotary kilns

Rotary kilns are among the most critical-and most thermally intense- units in cement production. They operate continuously under extreme heat, with internal temperatures reaching over 1,450°C. Maintaining optimal thermal balance along the kiln shell and inside the combustion zone is vital to ensure clinker quality, energy efficiency, and structural integrity.

Without proper monitoring, temperature fluctuations can cause premature refractory wear, damage to kiln tires or rollers, and unstable sintering conditions. Additionally, the increasing use of alternative fuels presents new combustion challenges, requiring even more precise thermal supervision.

External kiln shell monitoring with KILNSCAN

Full thermal coverage and real-time analysis

KILNSCAN is a high-resolution infrared scanner designed to continuously monitor the temperature of the kiln shell. Unlike spot measurements, it provides full circumferential thermal imaging across the entire kiln length. This comprehensive data enables operators to visualize hotspots, coating evolution, or brick failures before they escalate.

Operators can visualize coating build-up, compare thermal trends over time, and receive visual and numerical alerts when values deviate from normal tolerence. This ability to track thermal anomalies in real time enables faster decisions and reduces unplanned shutdowns.

Enhanced accuracy with reference pyrometer

Environmental factors and atmospheric conditions like humidity or weather episodes (fog, heavy rain, snow, etc.) can interfere with infrared readings. KILNSCAN addresses this through an optional reference pyrometer installed near the shell, which cross-checks scanner data and compensates for atmospheric absorption

The continuous comparison between pyrometer and scanner data helps maintain reliable monitoring 24/7, supporting consistent process control and refractory protection.

Monitoring mechanical stress - thermal crank - and tyre migration

Thermal inhomogeneities on the kiln shell can indicate structural stress, often invisible until damage occurs. KILNSCAN’s Thermal Warp Monitoring identifies these stress zones early by analyzing temperature-related distortion, especially around the tyres.

The system also measures tyre slip, even at extremely low speeds below 0.1 RPM. Monitoring this movement is especially crucial during heat-up or cool-down phases, when stress on the kiln structure can be at its highest.

Seamless integration and intuitive interface

KILNSCAN integrates with any plant control system and offers a comprehensive interface with graphical overlays, custom alarm zones, and historical data logging. The software also includes features like:

- Reference profile comparison

- Brick lining mapping

- Zonal temperature analysis

- OPC client, 4–20 mA analog outputs and digital outputs

Operators can configure up to 20 independent alarms based on max/min thresholds or temperature variations, ensuring real-time responsiveness across the kiln.

Internal flame and combustion control with PYROSCAN

High-resolution imaging for combustion insight

PYROSCAN is an advanced high-temperature camera system that delivers both thermal and visible images of the combustion process inside the kiln. It helps operators monitor flame stability, clinker chute temperatures, and burner performance in real time.

PYROSCAN captures a dynamic thermal view of the entire combustion zone. This includes real-time tracking of:

- Flame shape and trajectory (flame twist)

- Flame Temperature and temperature of the clinker fall.

- Burner behavior and blockages or rhino horn build ups

- Coating, Nose ring and cooler interface zones

Early detection of combustion anomalies

Fluctuations in flame shape or temperature often indicate deeper process issues—fuel quality changes, burner settings or misalignment, or air flow inconsistencies. PYROSCAN identifies these issues early, allowing maintenance teams to respond before they affect clinker formation or damage the kiln internals.

The system can also detect the development of “rhino horn” build-up on burner tips and the wear of the nose ring segments, both of which, if left unchecked, can result in major mechanical issues or efficiency losses.

Optimizing fuel usage and supporting decarbonization

PYROSCAN enables operators to fine-tune the burner and primary air settings to ensure complete combustion. This improves heat efficiency and helps reduce specific fuel consumption. For plants using alternative fuels, accurate flame monitoring is especially important to avoid incomplete combustion and emissions spikes.

PYROSCAN is also used in calcined clay applications, where combustion temperatures are lower than for clinker. The camera can be calibrated to suit the specific calcination temperature of clays, making it a valuable tool for low-carbon cement production trials.

Smart integration and digitalization features

Designed for Industry 4.0 readiness, PYROSCAN includes AI-compatible software features and robust interfacing options such as:

- OPC protocols (UA & DA)

- 4–20 mA analog outputs

- Live thermal video streams

- Unlimited zone configuration and related alarms

Its flexible interface and intuitive HMI allow operators to visualize, record, and export data for long-term analysis or automated control systems, including prediction softwares.

End-to-end monitoring from kiln to cooler

When paired together, KILNSCAN and PYROSCAN form a complete solution covering both external and internal thermal supervision of the rotary kiln. This combination provides full visibility into the kiln’s operation:

- KILNSCAN ensures the integrity of the shell, protects the refractory, and detects hotspots.

- PYROSCAN delivers insight into flame dynamics, burner performance, and the clinker bed.

Additionally, PYROSCAN can be installed in the clinker cooler to monitor grate temperatures, detect snowman formations or red rivers, and help regulate grate speed or air blower output for optimal cooling.

Rotary Kiln Thermal Monitoring SolutionKILNSCAN & PYROSCAN

Key benefits of rotary kiln thermal monitoring

Improve safety and prevent shutdowns

Real-time detection of hot zones, refractory wear, or flame instability allows plant personnel to take corrective action before damage occurs, reducing risk for both equipment and staff.

Increase equipment lifetime and reduce maintenance costs

By stabilizing thermal conditions and detecting early signs of failure, infrared monitoring protects kiln linings, rollers, bearings, and burners—minimizing costly downtime and part replacements.

Optimize energy use and reduce emissions

Thermal data helps fine-tune the combustion process and supports the shift to alternative fuels by ensuring complete and efficient combustion, contributing to CO₂ reduction targets.

Enhance clinker quality and production consistency

Stable temperature profiles inside and outside the kiln lead to more consistent sintering conditions, better clinker properties, and fewer off-spec batches.

Rotary kiln thermal monitoring is no longer just a safety feature—it’s a critical part of efficient, sustainable cement production. By providing live thermal maps, advanced diagnostics, and full integration with plant control systems, KILNSCAN and PYROSCAN empower cement manufacturers to reduce energy consumption, extend kiln life, and ensure consistent clinker quality.

Whether you’re modernizing an existing line or building a new plant, implementing real-time thermal monitoring, thermography instrumentation is a step toward smarter, safer, and more competitive cement manufacturing !