- Home

- ITH

- Applications

- Clinker Cooler

CLINKER COOLERThermal monitoring of clinker coolers for efficient cement production

Thermal monitoring of the clinker cooler to improve performance

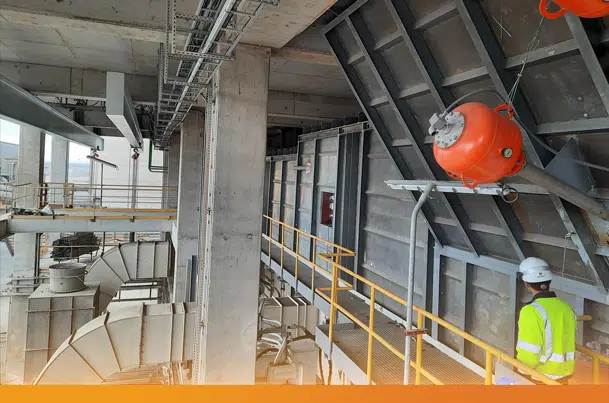

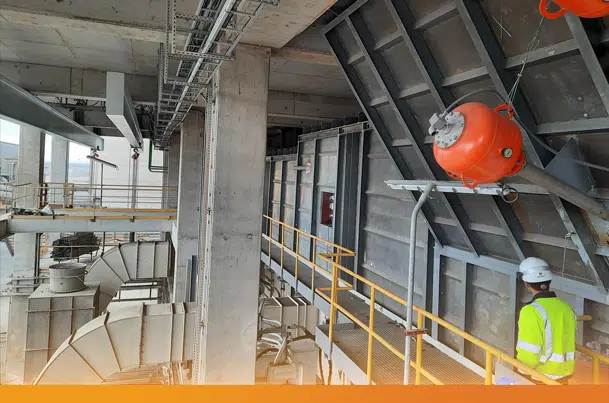

Efficient clinker cooling is a critical step in cement production. Advanced thermal monitoring technologies like Pyroscan can quickly detect phenomena that slow down production and optimize cooling processes to improve both safety and productivity. By integrating real-time thermal monitoring, cement plants can avoid costly downtime while maximizing efficiency.

Thermal monitoring of the clinker cooler is essential for cement production. Clinker, a hot product formed in the rotary kiln, requires careful cooling before being transported to the clinker storage or cement mill. Efficient cooling, combined with real-time thermal monitoring, ensures optimal production while protecting equipment and personnel. Inadequately cooled clinker inclusions can cause fires, damage to equipment, and operational downtime.

To address these risks, advanced thermal monitoring systems like PYROSCAN provide effective solutions that enable the rapid, optimizing the clinker cooling process and ensuring maximum safety and performance.

Why clinker cooler thermal monitoring is essential for cement plants

Clinker produced in the rotary kiln can exceed temperatures of 1,000°C. After exiting the kiln, it is transferred to a clinker cooler, typically a grate cooler, where air fans cool the clinker through the moving grates before it reaches the clinker silo or the cement mill via pan conveyors. This cooling process must be carefully managed to prevent damage and ensure safe handling as well as optimizing the productivity.

However, some clinker may not cool properly, resulting in hot inclusions that could cause fires, damage equipment, or halt production entirely. By continuously monitoring the temperature of the clinker during cooling with advanced thermal detection tools, uncooled areas can be quickly identified, allowing for swift corrective actions such as blowers speed or grates speed adjustments to prevent major issues.

How thermal monitoring systems work

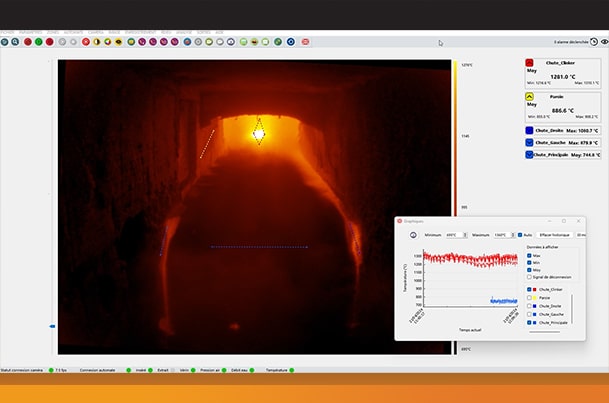

Real-time temperature detection and alerts

Pyroscan uses high-resolution thermal sensors to detect even minor temperature variations across the clinker bed. The collected data is sent to a central platform where operators can monitor temperature zones live.

Automated alerts notify staff when temperatures exceed thresholds, allowing for immediate intervention and risk mitigation

Snowman formation detection and automated air blaster activation

Clinker build-ups—known as “snowman” formations—can disrupt cooling. Pyroscan detects these formations and when interfaced with the DCS can automatically activates air blasters to eliminate blockages and restore proper flow.

Clinker bed and red river monitoring

Pyroscan tracks the clinker bed to ensure uniform cooling. It also detects “red river” events—high-temperature clinker streams that indicate imbalanced cooling—triggering alerts to adjust settings and prevent overheating.

Zoned temperature control and automated process optimization

Temperature zones within the cooler are independently monitored, enabling precise control over airflow and grate speed. Pyroscan adjusts these parameters in real time for optimal clinker cooling.

Real-time temperature detection and alerts

Pyroscan uses high-resolution thermal sensors to detect even minor temperature variations across the clinker bed. The collected data is sent to a central platform where operators can monitor temperature zones live.

Automated alerts notify staff when temperatures exceed thresholds, allowing for immediate intervention and risk mitigation

Snowman formation detection and automated air blaster activation

Clinker build-ups—known as “snowman” formations—can disrupt cooling. Pyroscan detects these formations and when interfaced with the DCS can automatically activates air blasters to eliminate blockages and restore proper flow.

Clinker bed and red river monitoring

Pyroscan tracks the clinker bed to ensure uniform cooling. It also detects “red river” events—high-temperature clinker streams that indicate imbalanced cooling—triggering alerts to adjust settings and prevent overheating.

Zoned temperature control and automated process optimization

Temperature zones within the cooler are independently monitored, enabling precise control over airflow and grate speed. Pyroscan adjusts these parameters in real time for optimal clinker cooling.

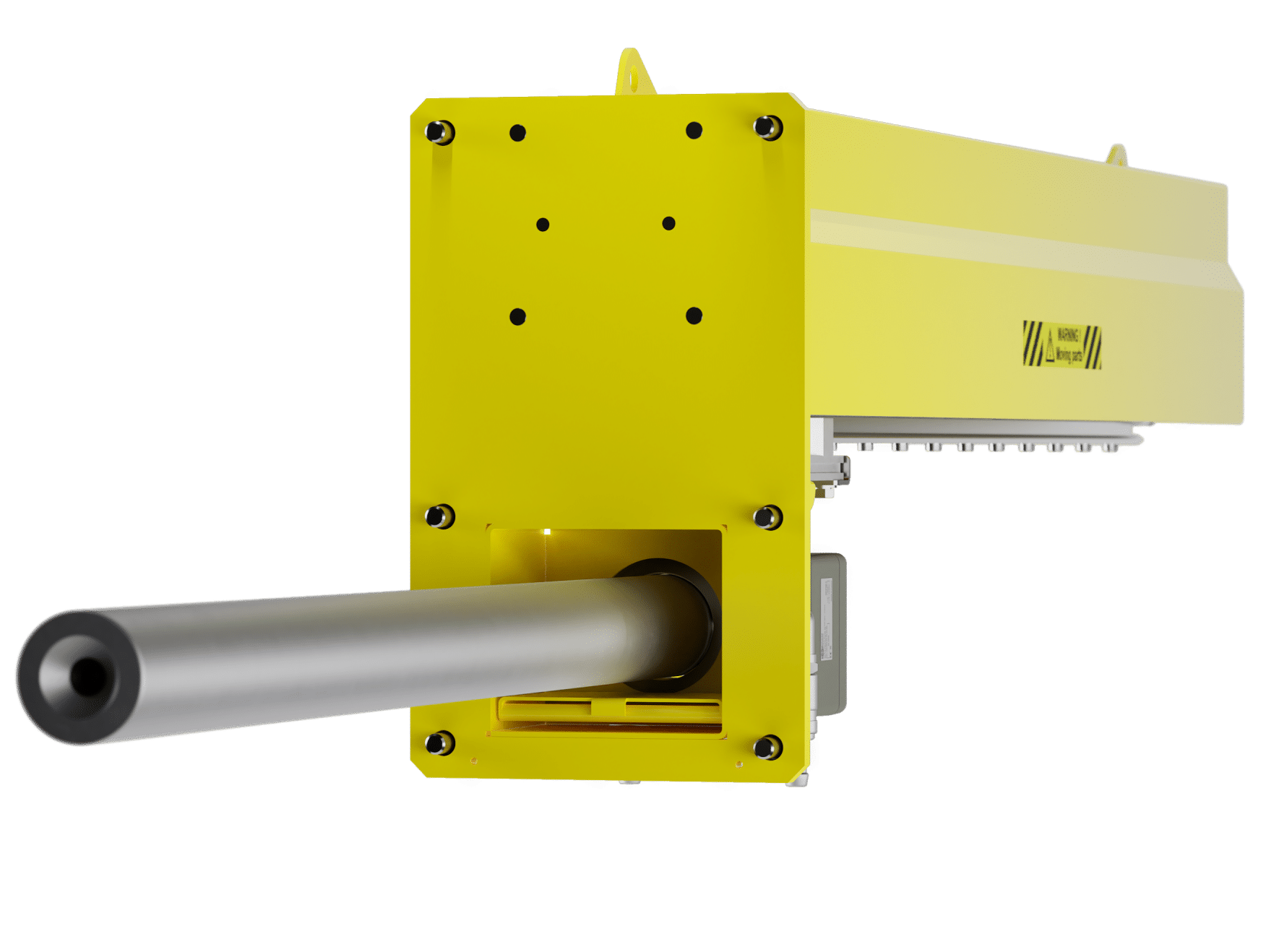

Why choose Pyroscan for clinker cooler thermal monitoring?With Pyroscan Advanced Pyrometric Imaging

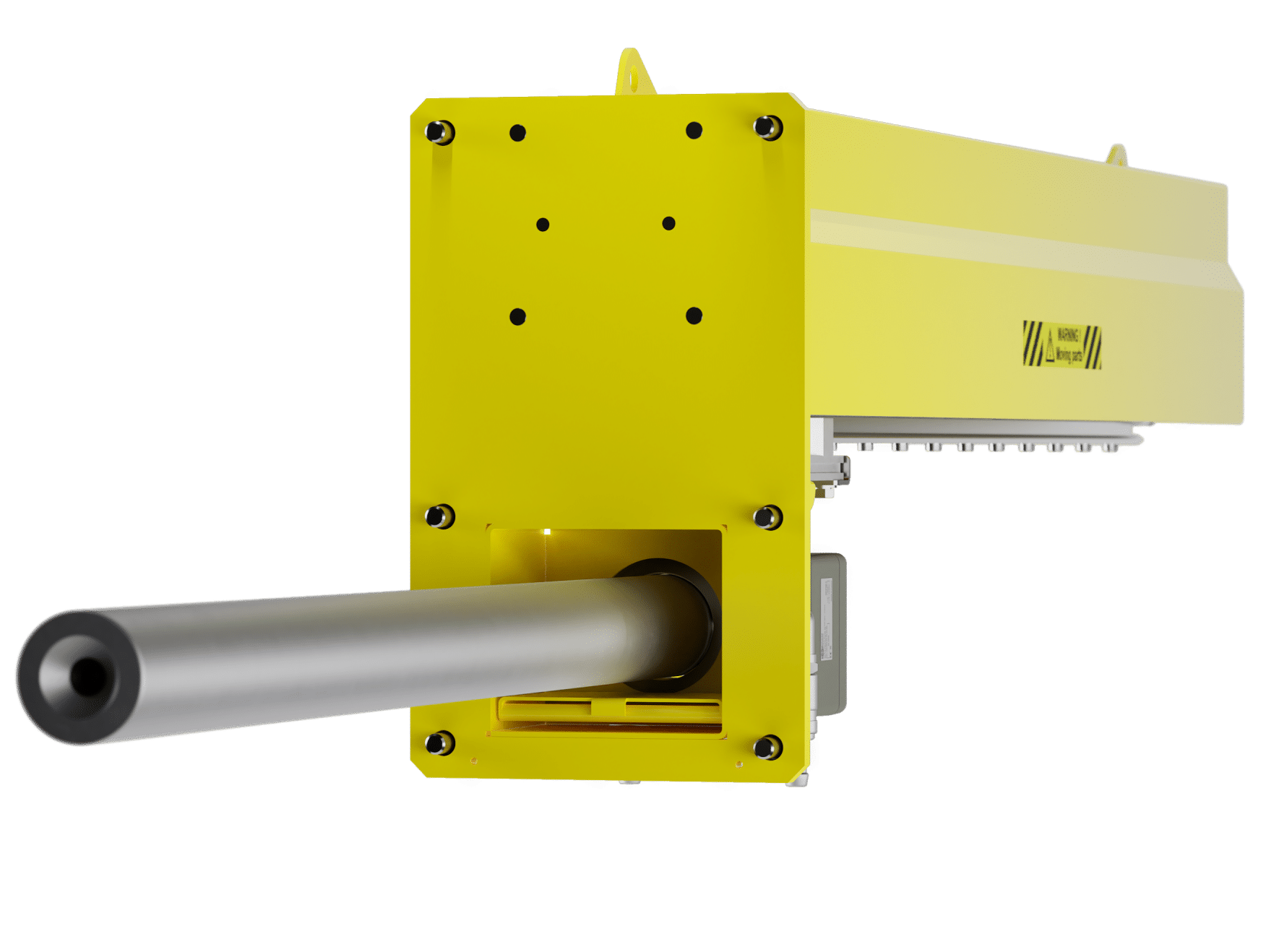

PYROSCAN

Pyroscan is a cutting-edge thermal monitoring solution designed to optimize the clinker cooling process. With its high-resolution temperature sensors, real-time data collection, and automatic adjustment capabilities, Pyroscan is the ideal tool for enhancing the safety, efficiency, and performance of your clinker cooler.

Pyroscan is especially effective in the challenging conditions of clinker coolers, ensuring precise temperature control and cooling process optimization.

Pyroscan also allows a close surveillance of snowman build up or red rivers formation for a smooth operation of the cooler.

Clinker cooler thermal monitoring is crucial for ensuring safe, efficient, and cost-effective cement production. With tools like Pyroscan, operators can quickly optimize the cooling process. By integrating this advanced technology into your plant, you can enhance clinker quality, improve safety, and increase overall productivity.

PYROSCAN

Pyroscan is a cutting-edge thermal monitoring solution designed to optimize the clinker cooling process. With its high-resolution temperature sensors, real-time data collection, and automatic adjustment capabilities, Pyroscan is the ideal tool for enhancing the safety, efficiency, and performance of your clinker cooler.

Pyroscan is especially effective in the challenging conditions of clinker coolers, ensuring precise temperature control and cooling process optimization.

Pyroscan also allows a close surveillance of snowman build up or red rivers formation for a smooth operation of the cooler.

Key benefits of clinker cooler thermal monitoring

Enhanced Safety

Early detection of temperature anomalies significantly reduces the risk of heat-related incidents. Pyroscan helps protect both personnel and equipment, minimizing industrial accidents.

Prevention of Equipment Damage

Undetected hot clinker inclusions can damage pan conveyors, belts, grates, crusher parts and other equipment. By ensuring that too hot inclusions are quickly identified, Pyroscan helps prevent costly repairs and prolongs the lifespan of equipment.

Optimized Production

Pyroscan provides real-time data and enables automated adjustments to ensure efficient clinker cooling. By maintaining consistent cooling rates, it reduces unexpected downtime and improves the overall productivity of the plant.

Cost Reduction

By minimizing risks like fires, equipment failures, and cooling inefficiency, Pyroscan helps reduce maintenance costs, insurance premiums, and operational disruptions, leading to long-term savings.