- Home

- Electro-Optical Tests

- Applications

- Focal Plane Array and Detector Testing

FOCAL PLANE ARRAY AND DETECTOR TESTINGNoise and Thermal Test and Detector Image quality improvement

The challenges of measuring noise levels on multi-channel analog detectors

The noise level of a detector is a key parameter to be measured but it is often difficult to measure it independently from the noise generated by its driving electronics. HGH developed a set of ultra-low noise electronics compatible with any CMOS detectors:

- Ultra low noise Bias voltages

- High slew rate Clock signals

- Low noise analog to digital converter and multiplexer

Thanks to these driving electronics fully controlled by Infratest–BIRD package software and combined with HGH’s high uniform and accurate optical sources such as DCN1000 or ISV, the main parameters of focal plane arrays can be accurately measured : temporal noise, NEP, NETD, Specific Detectivity, linearity, responsivity.

Precision Bias Voltage Generation

The bias voltage module offers up to 20 independently programmable, ultra-low noise channels. Its integrated current-limiting functionality ensures detector protection during testing.

Measuring and correcting distortion in wide field-of-view optics

HGH’ Clock generator allows to create any clock pattern based on 100 MHz master clock with user adjustable High and Low levels. The extremely high slew rate of the clock signal leads to negligible noise into the detector signals. Our clock generator is associated to a user friendly Pattern creation software allowing the operator to easily create any clock signal.

Low-Noise Analog-to-Digital Conversion and Multiplexing

A low-noise ADC is essential for accurate signal digitization from CMOS detectors. The HGH ADC 16-80 features:

- 16-bit A/D dynamic range

- Very low input noise

- GigE Vision output format after multiplexing the channels

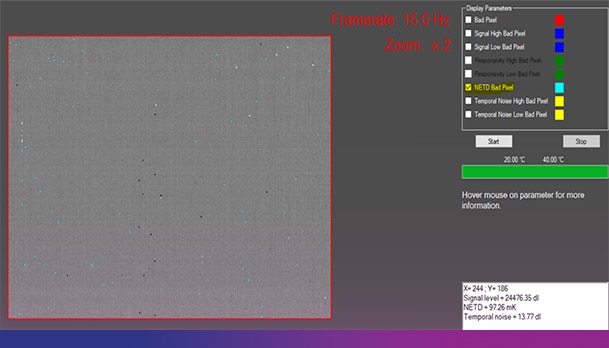

Image Quality Optimization: NUC and Bad Pixel Mapping

In addition to noise and thermal resolution measurements, INFRATEST dedicated software suite for the automated testing of sensors, allows to measure the following parameters in order to optimize the image quality at the output of the detector:

- Non-uniformity correction (NUC), based on a 2-point correction method

- Bad pixel and cluster detection and mapping, based on multiple criteria (signal level, NETD, responsivity)

Thanks to its user-friendly interface and compatibility with industry-standard equipment, INFRATEST accelerates both development and quality control processes, while ensuring reproducibility and accuracy.

High-Resolution Spectral Response Measurement

Spectral response testing demands exceptional accuracy and resolution. HGH developed a fully automated bench—controlled by INFRATEST—that generates a narrowband monochromatic signal from a blackbody spectrum. A meticulous low-noise calibration process enables:

- Spectral response curve generation with resolution better than 1% with BIRD test bench

- Fully automated operation and data acquisition via INFRATEST

Contact us to optimize your detector performance

Need to reduce noise levels on your CMOS detectors? Want to improve image quality with advanced calibration and bad pixel mapping?