- Home

- Electro-Optical Tests

- Applications

- Thermal Imagers Testing

THERMAL IMAGERSTest and parameters measurement solutions for high-performance infrared systems

Meeting the challenges of thermal imaging performance

Thermal imagers play a key role in a wide range of demanding applications, including:

- Surveillance and perimeter protection

- Thermal weapon sights and night vision goggles

- Automotive and marine navigation

- Unmanned aerial vehicles (UAVs)

- Infrared missile seekers

In all these cases, image quality and sensor accuracy are critical. To ensure optimal performance, manufacturers must carry out extensive testing during development and production. This includes verifying the imager’s ability to detect, recognize, and identify targets in various environmental conditions.

Precise measurement tools—designed specifically for infrared testing—are required to meet these industry standards. That’s where HGH comes in.

Reliable equipment for infrared sensor testing and qualification

Leading thermal imager manufacturers around the world rely on HGH’s specialized solutions to qualify their products. Our systems are used in both R&D laboratories and production lines, ensuring infrared devices meet performance expectations before they reach the field.

HGH provides an integrated approach, including:

- DCN1000 series blackbodies for radiometric accuracy and uniformity

- Collimators for resolution measurement, thermal contrast curve drawing and range calculation,

- Infratest software for automated testing and data analysis

Together, these tools enable complete characterization of forward looking thermal imagers, ensuring consistent quality and operational readiness.

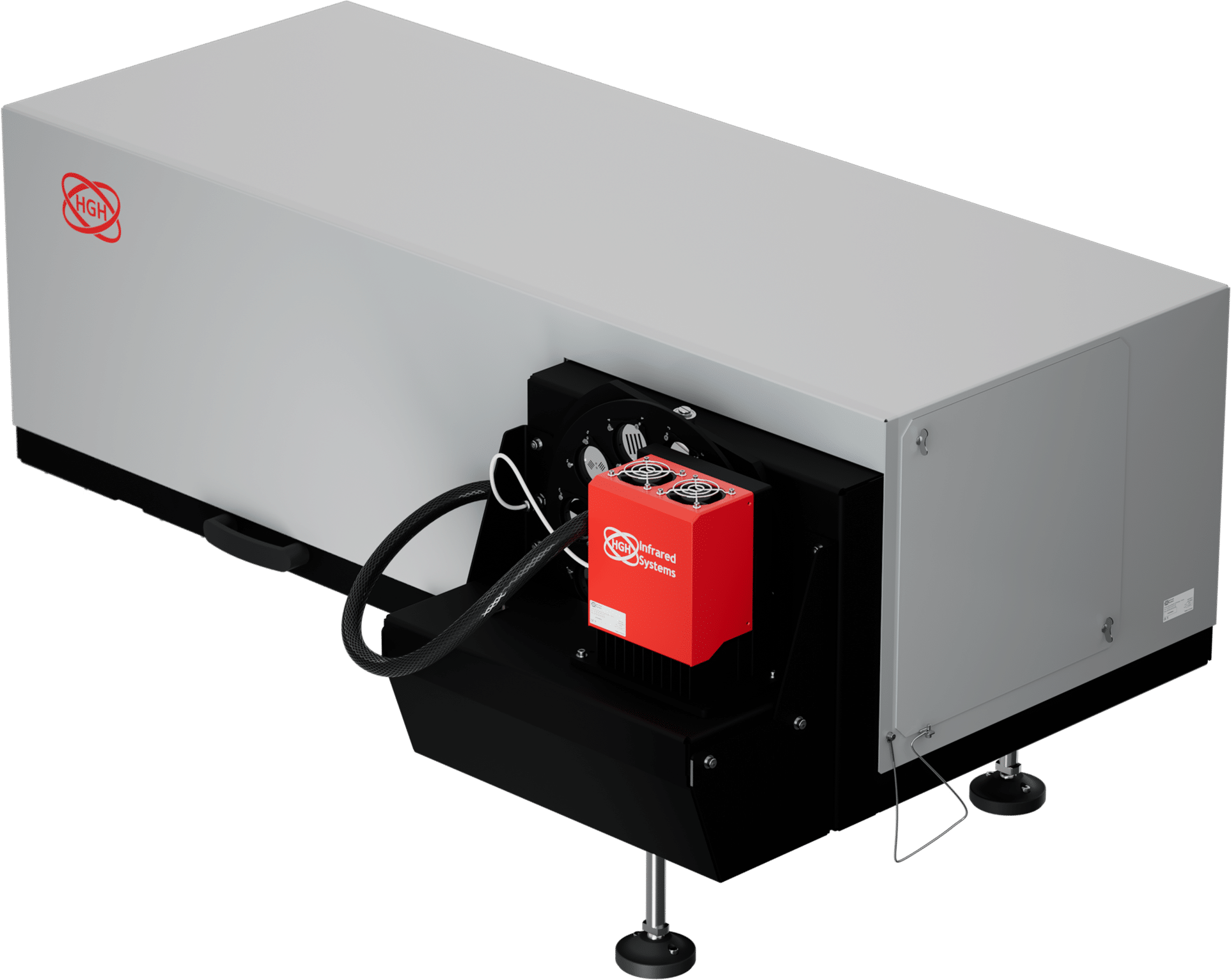

DCN1000 BlackbodiesPrecision thermal reference sources for thermal imagers testing

Our DCN1000 Blackbody series is designed for high-performance testing of infrared systems including thermal imagers. Key features include:

- Wide temperature ranges to simulate various scene scenarios

- Excellent surface uniformity for sensor testing consistency

- Radiometric calibration with certified accuracy

- Fast stabilization time for high throughput environments

Used in the Non-Uniformity Correction (NUC) process, DCN1000 blackbodies help manufacturers eliminate sensor-related image artifacts and improve thermal contrast.

DCN1000

Our DCN1000 Blackbody series is designed for high-performance testing of infrared systems including thermal imagers. Key features include:

- Wide temperature ranges to simulate various scene scenarios

- Excellent surface uniformity for sensor testing consistency

- Radiometric calibration with certified accuracy

- Fast stabilization time for high throughput environments

Used in the Non-Uniformity Correction (NUC) process, DCN1000 blackbodies help manufacturers eliminate sensor-related image artifacts and improve thermal contrast.

COLLIMATORSTesting spatial performance and ranges

HGH collimators are essential for assessing the spatial resolution of thermal imagers. They simulate distant targets in a controlled optical setup and are commonly used to determine key parameters such as:

- Spatial resolution and detector focusing through Modulation Transfer Function (MTF)

- Thermal contrast curve drawing through

- Minimum Resolvable Temperature Difference (MRTD) method

- Triangle Observation Discrimination (TOD) method

- Detection, Recognition, and Identification ranges (DRI)

- Field of View and Distortion measurement.

Our collimators are compatible with various infrared test patterns and integrate seamlessly with our Blackbodies and INFRATEST software for full test automation.

COLLIMATORS

HGH collimators are essential for assessing the spatial resolution of thermal imagers. They simulate distant targets in a controlled optical setup and are commonly used to determine key parameters such as:

- Spatial resolution and detector focusing through Modulation Transfer Function (MTF)

- Thermal contrast curve drawing through

- Minimum Resolvable Temperature Difference (MRTD) method

- Triangle Observation Discrimination (TOD) method

- Detection, Recognition, and Identification ranges (DRI)

- Field of View and Distortion measurement.

Our collimators are compatible with various infrared test patterns and integrate seamlessly with our Blackbodies and INFRATEST software for full test automation.

INFRATEST : The smart, turnkey software for thermal imager testing

INFRATEST is HGH’s dedicated software suite for the automated testing of thermal imagers. It supports full characterization of infrared cameras and sensors, including:

- Non-uniformity correction (NUC)

- Bad pixel detection and mapping

- Noise Equivalent Temperature Difference (NETD) measurement

- Thermal contrast curve (MRTD, TOD) generation for performance benchmarking

Thanks to its user-friendly interface and compatibility with industry-standard equipment, INFRATEST accelerates both development and quality control processes, while ensuring reproducibility and accuracy.

A complete testing ecosystem for thermal imagers

By combining precision temperature sources, optical test tools, and software automation, HGH provides a comprehensive testing environment for thermal imagers at all stages of their lifecycle.

Contact us to build your test bench !

Looking to enhance the precision and reliability of your thermal imager testing?