Reducing Carbon Footprint with Furnace Combustion Monitoring

In a world facing increasingly urgent environmental challenges, waste incineration plays a pivotal role in our quest to preserve the planet. In this article, we explore why monitoring furnace combustion is a key issue in modern ecology. Innovative solutions proposed by HGH Infrared Systems can contribute to shaping a more sustainable future for our planet while enhancing the efficiency of industrial facilities and optimizing their environmental impact: discover how!

Table of Contents

The Crucial Importance of Furnace Combustion Monitoring in Waste Treatment Plants

Environmental Consequences of Waste Incineration

Waste incineration is an inevitable step in waste management, especially when other methods like recycling or composting are not viable. However, this practice is not without consequences on the environment. Greenhouse gas emissions and various atmospheric pollutants it generates significantly contribute to climate change and air quality deterioration. This underscores the need for meticulous management of this process.

The Importance of Furnace Combustion Monitoring to Minimize Environmental Impact

Monitoring furnace combustion in waste treatment plants is crucial. By monitoring in real-time and precisely adjusting combustion parameters, these facilities can minimize their environmental impact. This effective monitoring ensures that furnaces operate optimally, thereby reducing harmful emissions while maximizing energy efficiency. It’s a delicate balance between the need to incinerate waste and the environmental responsibility these plants bear.

The Challenges of Waste Incineration

A Significant Contribution to the Climate Crisis

Environmental challenges stemming from waste incineration are vast and varied, casting a significant shadow on waste management practices. It’s imperative to understand that waste incineration is not just a means of disposal but a process with profound environmental repercussions. It substantially contributes to the global issue of climate change by emitting greenhouse gases, especially carbon dioxide (CO2). These emissions, while serving a practical role in waste disposal, directly exacerbate the global climate crisis.

Waste Incineration: Impact on Air Quality and Human Health

Waste incineration is an inevitable step in waste management, especially when other methods like recycling or composting are not viable. However, this practice is not without consequences on the environment. Greenhouse gas emissions and various atmospheric pollutants it generates significantly contribute to climate change and air quality deterioration. This underscores the need for meticulous management of this process.

Advanced Monitoring Solutions for Sustainable Ecology

Temperature Control in the Incinerator: From Precise Measurement to Intelligent Analysis

In a world where waste management is crucial for environmental preservation, innovative approaches are imperative to minimize our ecological impact. Municipal waste incineration plants play a crucial role in this quest, converting waste into energy while minimizing final waste. Yet, this process is not without challenges: waste incineration involves burning organic substances in standard municipal and industrial solid waste. To ensure complete combustion of these organic materials, incinerators must reach high temperatures, typically between 850°C and 1100°C. Precise temperature control is crucial for optimizing efficiency.

This is where HGH Infrared Systems’ advanced monitoring solutions come into play:

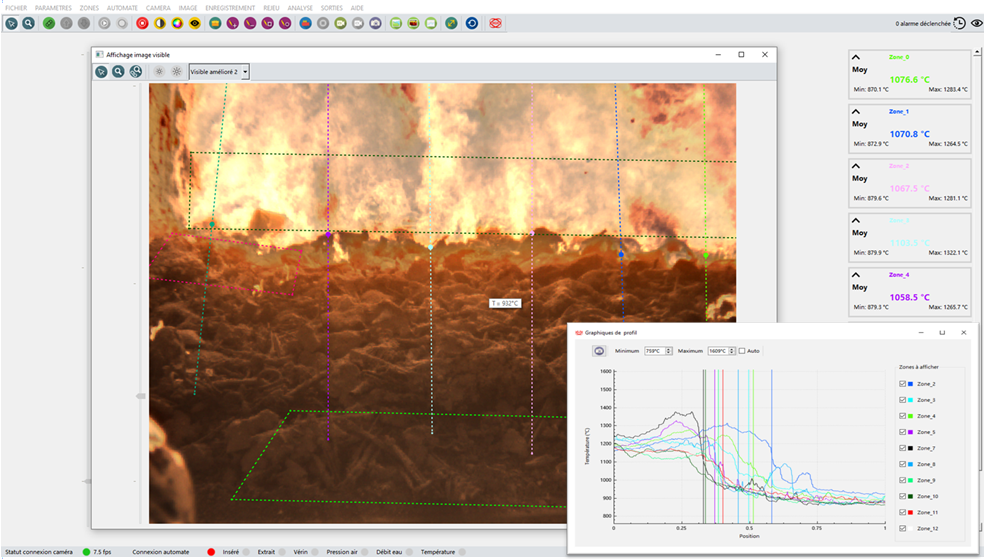

• Precise measurement of temperature on incineration grates

• Flame front detection

• Automatic analysis of this data to facilitate operator decision-making

• Measurement of slag temperature

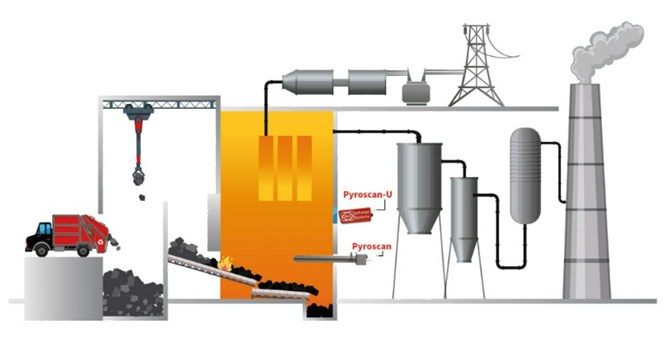

Our ultra-resistant thermal cameras PYROSCAN and PYROSCAN-U are specially designed to monitor and control these demanding thermal processes. PYROSCAN can be equipped with an automated insertion/retraction mechanism, allowing for close-up images near the area of interest without compromising signal quality. PYROSCAN-U, on the other hand, is installed outside the high-temperature combustion zone, providing continuous and reliable monitoring.

Spotlight on… Precise Flame Front Detection:

The precise location of the flame front is essential for the effective operation of the incinerator. Real-time accurate detection of the flame front allows the furnace control system to adjust the grate speed and air flow, ignite burners as needed, and optimize the entire process. HGH has developed a dedicated algorithm in partnership with global leaders in waste incineration to provide real-time flame front detection.

In conclusion, monitoring furnace combustion in waste treatment plants is a crucial step to preserve our environment. Through HGH Infrared System’s advanced monitoring solutions, industries can actively play a role in reducing their ecological footprint while improving operational efficiency. By investing in cutting-edge technologies, we can progress towards a more sustainable future where waste management no longer compromises the health of our planet.