- Home

- ITH

- Applications

- Waste to energy

WASTE TO ENERGYOptimizing the waste incineration process in waste-to-energy plants

Waste incineration process thermal monitoring: Optimizing combustion efficiency

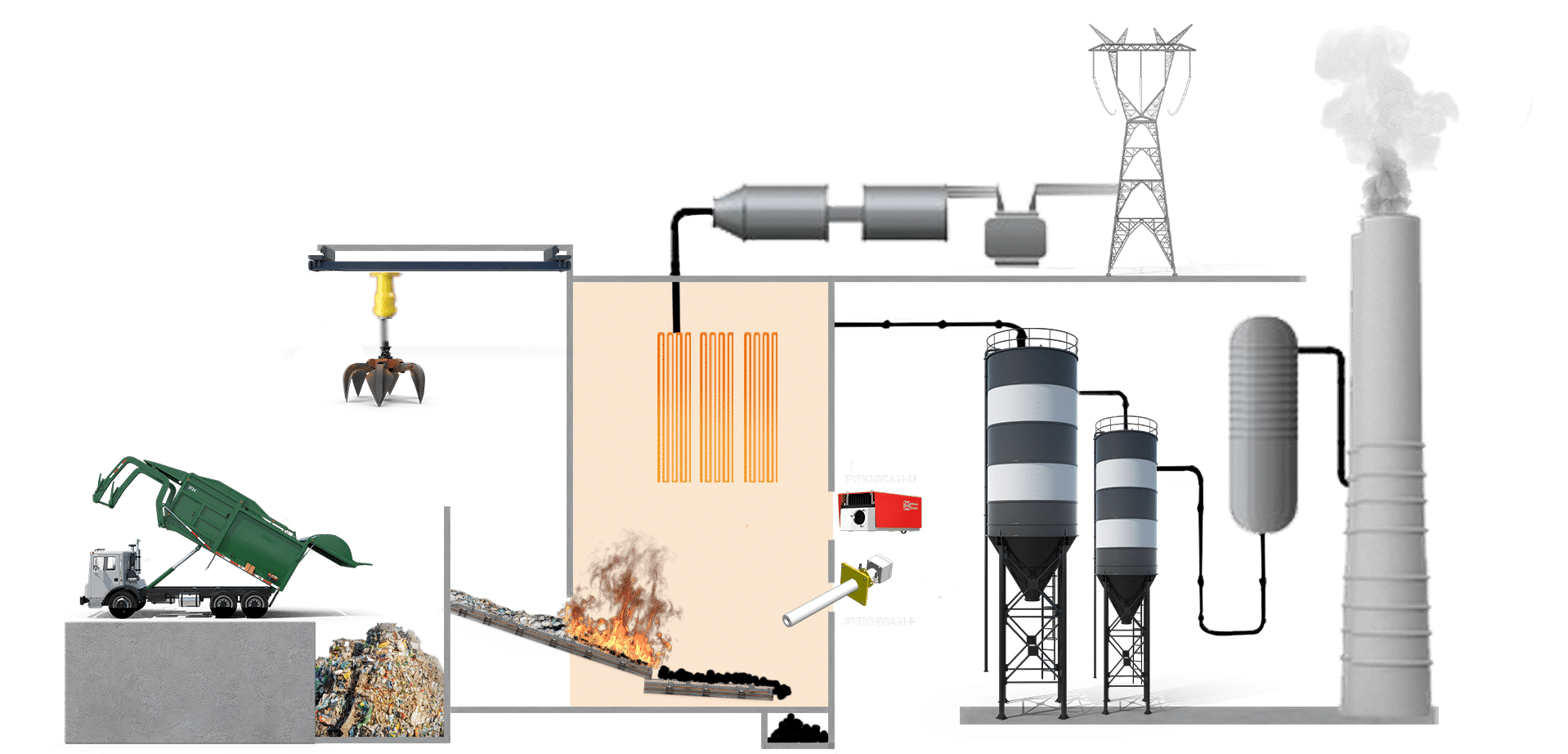

The waste incineration process is a key component of waste-to-energy plants, where municipal and industrial waste is converted into valuable energy such as heat (steam) and power. However, to maximize the efficiency of this process, waste incineration plants must continuously refine their operations. A critical area for improvement lies in optimizing combustion, particularly within the high-temperature environment of the grate furnaces where the waste incineration process begins.

By accurately monitoring and optimizing the combustion phase, plant operators can increase steam production per ton of waste and enhance the quality of the slag, making it more valuable. Effective thermal monitoring of the combustion process plays a central role in achieving these improvements, ensuring optimal energy recovery and overall plant performance.

Flame front detection: A crucial feature for the waste incineration process

An important aspect of optimizing the waste incineration process is controlling the flame front—the exact point where combustion ceases. Accurately managing the flame front location enables better regulation of combustion, improving both efficiency and energy recovery.

HGH’s flame front detection function is designed specifically for the waste incineration process. Developed in partnership with global leaders in waste-to-energy, this real-time, precise flame front detection ensures that the combustion process can be dynamically adjusted for optimal performance.

The location of the flame front is transferred in real time to the furnace control system, allowing it to make necessary adjustments, such as:

- Grate speed: Adjusting the rate at which waste moves through the furnace.

- Air flow: Controlling airflow to optimize combustion.

- Burner activation: Activating additional burners to support combustion if needed.

These adjustments ensure that heat is released efficiently and that the combustion process operates within ideal parameters, minimizing energy waste and maximizing efficiency.

An important aspect of optimizing the waste incineration process is controlling the flame front—the exact point where combustion ceases. Accurately managing the flame front location enables better regulation of combustion, improving both efficiency and energy recovery.

HGH’s flame front detection function is designed specifically for the waste incineration process. Developed in partnership with global leaders in waste-to-energy, this real-time, precise flame front detection ensures that the combustion process can be dynamically adjusted for optimal performance.

The location of the flame front is transferred in real time to the furnace control system, allowing it to make necessary adjustments, such as:

- Grate speed: Adjusting the rate at which waste moves through the furnace.

- Air flow: Controlling airflow to optimize combustion.

- Burner activation: Activating additional burners to support combustion if needed.

These adjustments ensure that heat is released efficiently and that the combustion process operates within ideal parameters, minimizing energy waste and maximizing efficiency.

Real-time thermal monitoringFor the waste incineration process

HGH provides an advanced solution for monitoring the waste incineration process: the Pyroscan rugged HDR pyrometric camera. This high-temperature thermal imager offers precise, real-time temperature measurements of the combustion zone, allowing operators to optimize the combustion process for improved efficiency and performance.

PYROSCAN

Pyroscan (with water-cooled endoscope): Ideal for capturing images close to the combustion zone without any signal attenuation, ensuring reliable temperature data.

Pyroscan-U: Installed outside the high-temperature combustion zone, this model captures the calcination area through a standard window and requires no cooling.

PYROSCAN

Pyroscan (with water-cooled endoscope): Ideal for capturing images close to the combustion zone without any signal attenuation, ensuring reliable temperature data.

Pyroscan-U: Installed outside the high-temperature combustion zone, this model captures the calcination area through a standard window and requires no cooling.

Both Pyroscan models offer flexible, robust solutions to monitor the waste incineration process, whether inside or outside the furnace, ensuring optimal performance in various high-temperature environments.

Integrated software for thermal and visual monitoring

The Pyroscan thermal cameras are paired with a dedicated, intuitive software solution that processes thermal images and provides powerful tools for analyzing the temperature data within the waste incineration process. This software offers a real-time, simultaneous display of both visible and thermal images, providing operators with clear insights into combustion dynamics.

Key features include:

- Real-time display of both visible and thermal images

- Seamless integration with plant control systems via OPC links and 4-20 mA

- Exclusive flame front detection, optimized for the waste incineration process

Key benefits of thermal monitoring in the waste incineration process

Enhanced operational safety and integrity

- Early detection of combustion anomalies, enabling proactive mitigation of risks.

- Protection of both personnel and equipment from potential hazards.

Predictive maintenance and reduced downtime

- Real-time data helps anticipate and address maintenance needs before problems arise.

- Extending the lifespan of equipment and minimizing costly operational interruptions.

Optimized flow and rate capacity

- Ensuring complete and uniform combustion of all organic material in the waste.

- Maximizing energy recovery, resulting in greater output from each ton of waste incinerated.

User-friendly operational management

- A simple, intuitive interface that makes it easy to navigate and interpret thermal data.

- Empowering operators with actionable insights and streamlined control of the waste incineration process.

Environmental compliance

- Precise control over the combustion process reduces harmful emissions.

- The waste incineration process remains compliant with stringent environmental regulations and sustainability goals.

Increased profitability and ROI

- Reducing the risk of breakdowns and halts in production, ensuring consistent energy production.

- Higher efficiency leads to increased profitability by maximizing the energy recovered from waste.

- Controlling the quality and valorisation of the slag

By implementing advanced thermal monitoring systems like HGH’s Pyroscan cameras and dedicated software, waste-to-energy plants can achieve greater efficiency, improved safety, and enhanced environmental compliance. Real-time monitoring and precise flame front detection play pivotal roles in optimizing the waste incineration process, ensuring optimal energy recovery, reducing maintenance costs, and increasing the plant’s overall performance.