New generation Blackbody Controller

An advanced technology revolutionizing Blackbodies’ capabilities

The most advanced generation of Blackbody controllers

HGH understands the importance of the Human-Computer Interface in the maintenance and testing of electro-optical devices.

To anticipate the market’s needs, we imagined, developed and designed the most advanced generation of Blackbody controllers, placing the blackbody at the core of the IR camera testing system.

This new generation of electronic controllers is at the heart of the blackbody control and monitoring. Ideally suited for the testing and calibration of infrared systems, this advanced generation of blackbody controllers has an intelligent design allowing to achieve an unequalled performance level, with a 0.1 mK temperature resolution and a 0.5mK regulation stability.

3 Key Points

Compact: size reduced to 2U

Simple HCI: user friendly & intuitive

Multiple spectral ranges calibration capability

BB CONTROLLER

Improved ergonomics and a modern design

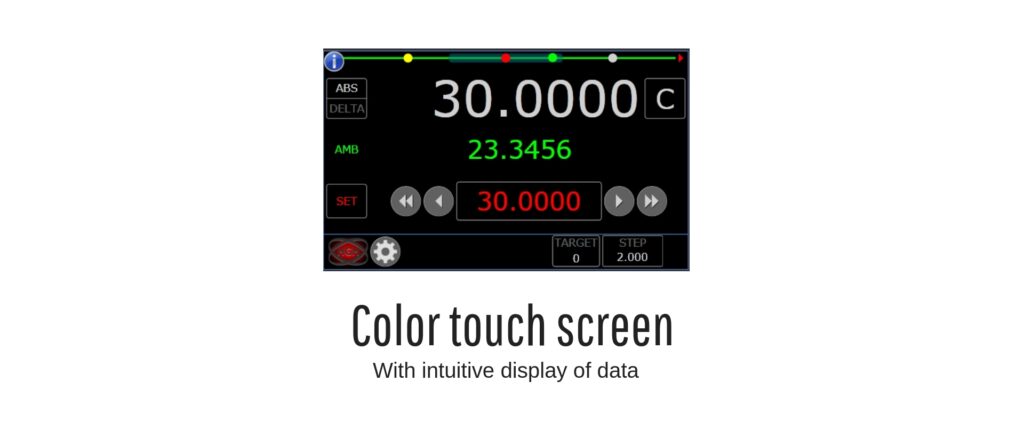

– Capacitive color touch screen with intuitive display of data and functions

– Compact: size reduced to 2U, for all types of Blackbodies

– Rackable, retractable feet

– Hearing comfort: management of fans’ operation

– Simple HCI: user friendly & intuitive, with color codes

Enhanced communication abilities for the blackbody

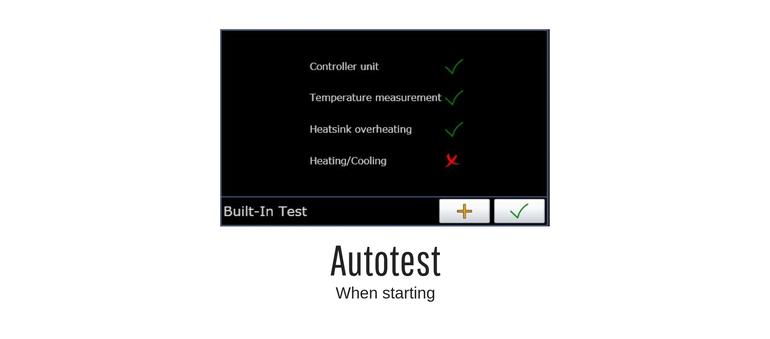

– Launching of an autotest when starting, to ensure the proper functioning of the Blackbody

– Creation of a Blackbody status file for easy maintenance

– Interchangeability between head and controller: blackbody management is as easy as possible

– Multi-spectral management of radiometric calibration: immediate transition from testing a MWIR sensor to testing a LWIR sensor, and vice-versa!

– True RADIATED temperature = DISPLAYED temperature: less uncertainty in IR sensor calibration

– The use of blackbodies in climatic chambers is simplified and more accurate than ever: the compensation of calibration tables depending on the temperature is entirely automatic

– The new controller is entirely compatible with the communication protocole of the previous generation: no need to modify your software or to change your Blackbody’s head

– Ethernet, IEEE and RS232 communications are available simultaneously

– Integrated control of the accessories: refrigerating unit

Unrivalled level of performance for years to come!

– Time spent on MRTD procedure now reduced by half thanks to the unequalled high slew rate and fast stabilization time

– Real-time display of the renowned DCN1000 Blackbody range’s temperature with a 0.1 mK resolution and regulation stability at 0.5 mK

– Integration of multiple calibration & correction tables and improvement of calibration accuracy through new fitting algorithm

– Thermometric calibration of sensors available, and easy for the operator