Visible to Infrared detector testing - IR Focal Plane Arrays

Optimize Detector Testing - IR Focal plane arrays testing with BIRD Test Bench:

Discover how to optimize detector testing and qualify multi-element optical detectors from the visible to far infrared spectrum with NETD, MTF, non uniformity, bad pixel tests and more.

The Evolution of IRFPA Technology:

The landscape of infrared imaging technology has witnessed a remarkable evolution in recent years, driven by the unrelenting demand for superior performance in day and night vision systems. IRFPA manufacturers, at the forefront of this technological revolution, have pushed the boundaries of what is possible in detector array design. This evolution can be attributed to several key factors, including the demand for Higher Resolution, Finer Dot Pitches, Expanded Spectral Ranges, and the need to optimize detector testing:

- Demand for Higher Resolution: The quest for sharper, more detailed images in day and night vision systems has prompted manufacturers to increase the number of pixels within detector arrays. This results in finer spatial resolution, allowing users to discern intricate details even in challenging environments.

- Finer Dot Pitches: To accommodate an ever-growing pixel count, IRFPA manufacturers have innovated in dot pitch reduction. Smaller dot pitches enable tighter packing of pixels on the focal plane array, further enhancing image quality and overall system performance.

- Expanded Spectral Ranges: Modern day and night vision systems are expected to operate across a wide range of wavelengths, from visible light to the infrared spectrum. As a response to this demand, IRFPA manufacturers have expanded the spectral ranges of their arrays, enabling systems to capture critical data across different lighting conditions and environmental scenarios.

IRFPA: The Challenges to Optimize Detector Testing

The realm of technology has always been advancing at an unprecedented rate. However, the introduction of technologies such as infrared focal plane arrays (IRFPA) has expressed new challenges that we must face as a technical community. These IRFPAs have undoubtedly transformed the way we gain visibility in both day and night vision capabilities. Nevertheless, due to the increasing complexity and denseness of the arrays, a new intricate and demanding task has arisen in the form of accurately assessing their key characteristics. The IRFPAs capturing a broader range of wavelengths has only made this task more challenging. We must be vigilant in our approaches to testing and measurement to ensure that these advancements continue to revolutionize the field while maintaining a high level of efficiency and accuracy.

Discover the BIRD Test Bench by HGH

In today’s fast-paced world, technological advancements have brought with them both opportunities and challenges. As manufacturers strive to keep up with the ever-evolving demands of the market, they face the challenge of ensuring that their products are not only cutting-edge but also efficient and reliable. This is especially true for manufacturers of infrared focal plane array (IRFPA) technology. Luckily, HGH’s BIRD bench, with its state-of-the-art features, has emerged as the ultimate solution to all the challenges manufacturers face.

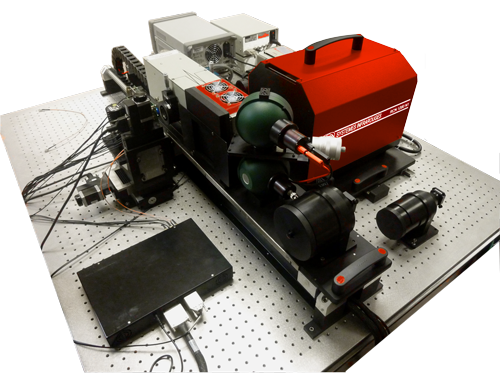

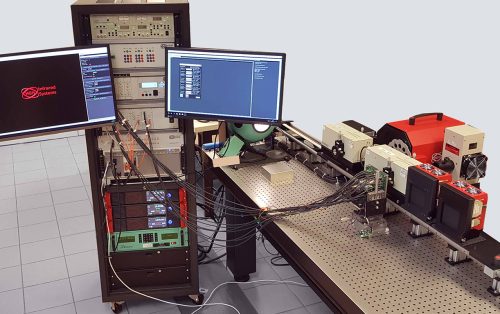

Designed to meet the demands of advanced IRFPA technology, the BIRD bench doesn’t just streamline the detector testing process but also optimizes it for optimal performance. With a comprehensive setup that includes an optical table with reference sources and monochromator, a control cabinet with signal generators, amplifiers, and controllers, and software for data acquisition and processing, manufacturers can confidently conduct accurate and efficient testing of their arrays. This ensures that their products deliver optimal performance in the field, and meet the high expectations of today’s discerning users. By utilizing the BIRD bench, manufacturers become masters of advanced IRFPA technology, producing products that excel in day and night vision systems.

Why use BIRD Test Bench to optimize detector testing:

Qualification of multi-element optical detectors

Integrated system

Very high precision