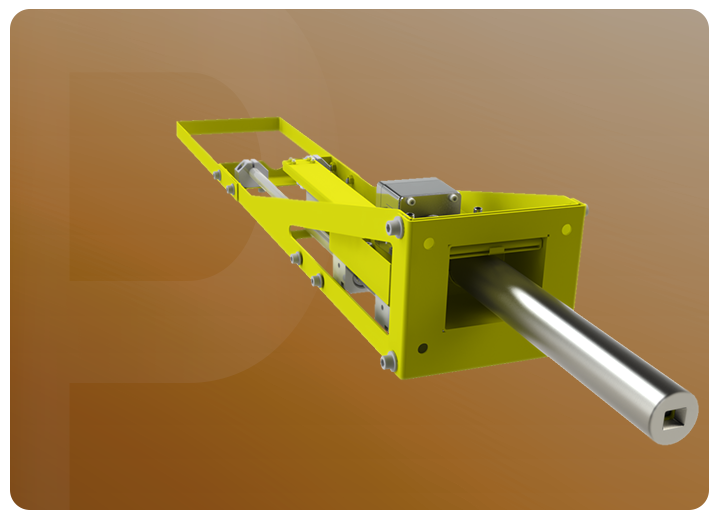

Kiln scanners which continuously monitor kiln shell temperature, have proven to play a key role in the economic performance of the cement production process.

In the cement industry, saving on operating costs is partly linked to keeping equipment running longer and more efficiently, reducing risk of unexpected shutdowns, and optimizing preventive maintenance operations. In particular, the kiln shell has to be under close surveillance.

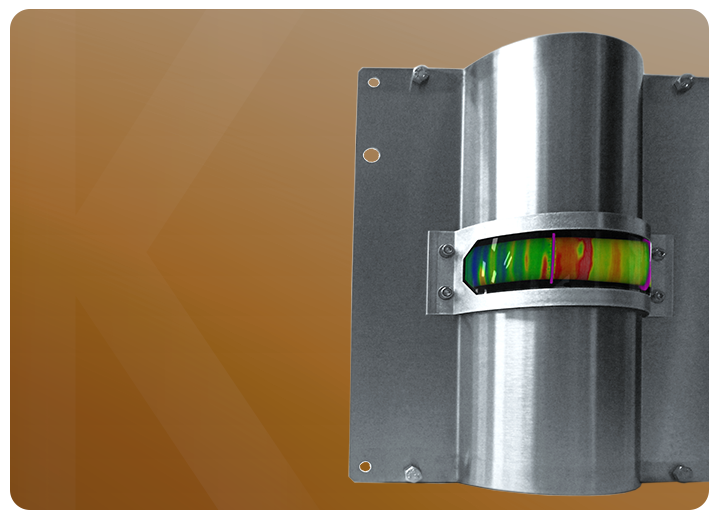

High performance infrared sensors can provide live temperature data on the kiln shell as it rotates. They allow control room operators to put the kiln shell under 24/7 high surveillance and via the shell thermal map display, show when alarm levels on critical parameters such as hot spot detection, tyre slip out of range or coating loss are reached.

However, Thermal scanners are not only emergency warning tools. They can integrate valuable features, useful to the maintenance manager, to schedule preventive actions and extend kiln lifetime.

HGH’s scanners and cameras enable the full heating process monitoring. Combining live and stored data, on kiln critical parameters, such as global temperature map, brick and coating thickness, kiln speed, tyre slip and thermal warp, Kilnscan provides accurate measurements:

HGH’s Kilnscan and Pyroscan systems are not only emergency warning tools, but can assist maintenance staff in establishing a predictive maintenance program.