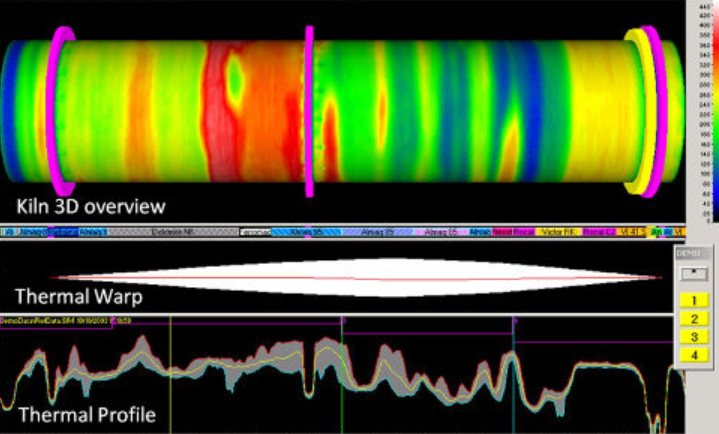

Scanners are well-known tools for operators of rotating kilns. Their use has become standard in many industries, where they help operators to monitor the temperature of the shell, they provide real-time information and warning about hot spots, excessive coating inside the kiln, insufficient Tyre Slip…

Kilnscan scanners offer a unique feature that contributes both to preserving equipment lifespan and production efficiency: the Thermal Warp computation. This function assesses in real-time the shell’s trend to bend due to thermal inhomogeneities along its surface.

Combined with the rotation of the kiln and with its load, a trend to bend induces cyclical flexions and efforts along the kiln which contribute towards degrading the long-term reliability of the installation. It generates load fluctuations on tyres and rollers and may warp the tyres. Even if their amplitude is small, periodical flexions of the shell generate local oval distortions, stressing the lining inside and reducing its lifetime. The drive system of the kiln is also subject to cyclical stresses which may cause excessive fatigue load.

If it is not detected and corrected in time, Thermal Warp may turn into permanent damages and distortion of the shell which will only be diagnosed during kiln alignment operations, usually carried out every few years. It also accelerates the ageing and wear of all kiln drive mechanisms and supporting structure.

As KILNSCAN scanners collect very accurate measurements, it is possible to know the exact temperature at each point of the shell, hence thermal inhomogeneities.

This allows HGH’s Thermal Warp Monitoring algorithm to provide real-time information about the trend of the shell axis to bend. An animated view of the kiln axis is displayed to the operator, together with a graph showing the amplitude of the potential lateral movement of the shell. The operator can take fast corrective actions such as adjusting the rotation speed, the geometry of the flame or the mix of the raw meal to restore homogeneous coating, for instance.

Thanks to Thermal Warp Monitoring, the contribution of KILNSCAN goes beyond real-time refractory and process monitoring as they support short-term actions to prevent long-term wear and damages to the kiln.

The medium and long-term evolution of the Thermal Warp data provides information on the process development inside the kiln, including the development of coatings, kiln push of unburnt material and flame adjustment. It also can be a valuable indicator of mechanical and thermal stresses in the shell and the tires as well as of load fluctuation supported by each pier.

Combined with Tire Slip monitoring, which is the measurement of the clearance between the kiln shell and its supporting tires, Thermal Warp monitoring helps assessing the shell geometry, the degree of deviation (ovality), eccentricity and misalignment.