- Accueil

- ITH

- Applications

- Four rotatif

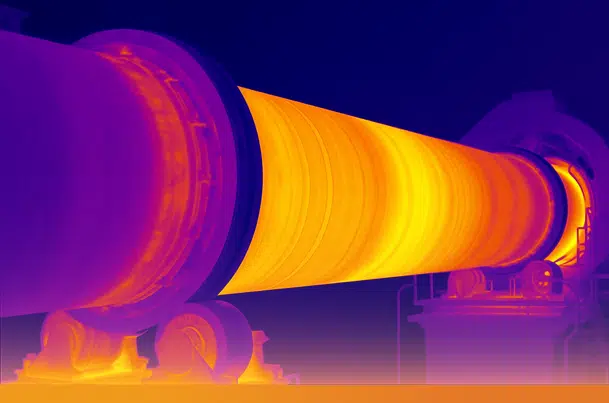

Surveillance thermique du four rotatif pour une production de ciment plus sûre et plus efficace

Surveillance thermique du four rotatif pour la performance, la sécurité et l'efficacité

Les fours rotatifs sont au cœur de la fabrication du ciment, et leur performance influence directement l’efficacité de la production, la consommation d’énergie et la durée de vie des équipements. Les systèmes avancés de surveillance thermique comme KILNSCAN et PYROSCAN offrent une visibilité en temps réel sur les conditions externes et internes du four, aidant les opérateurs à améliorer le contrôle, assurer la sécurité et prolonger la durée de vie des composants critiques. Découvrez comment la technologie infrarouge transforme les opérations des fours grâce à des prises de décision précises basées sur les données.

Pourquoi la surveillance thermique est essentielle dans les fours rotatifs

Les fours rotatifs font partie des unités les plus critiques et les plus thermiquement intenses de la production de ciment. Ils fonctionnent en continu avec une chaleur extrême, avec des températures internes dépassant les 1 450°C. Maintenir un équilibre thermique optimal le long de la virole du four et à l’intérieur de la zone de combustion est crucial pour garantir la qualité du clinker, l’efficacité énergétique et l’intégrité structurelle du four.

Sans une surveillance adéquate, les fluctuations de température peuvent entraîner une usure prématurée des réfractaires, des dommages aux bandages ou aux galets du four, et des conditions de friction instables. De plus, l’utilisation croissante de combustibles alternatifs présente de nouveaux défis de combustion, nécessitant une supervision thermique encore plus précise.

Surveillance de la virole externe du four avec KILNSCAN

Couverture thermique complète et analyse en temps réel

KILNSCAN est un scanner infrarouge haute résolution conçu pour surveiller en continu la température de la virole du four. Contrairement aux mesures ponctuelles, il fournit une imagerie thermique sur toute la circonférence du four, le long de sa longueur. Ces données complètes permettent aux opérateurs de visualiser les points chauds, l’évolution du croûtage ou les défaillances des briques réfractaires avant qu’elles ne s’aggravent.

Les opérateurs peuvent visualiser l’accumulation du croûtage, comparer les tendances thermiques au fil du temps et recevoir des alertes visuelles et numériques lorsque les valeurs s’écartent des tolérances normales. Cette capacité à suivre les anomalies thermiques en temps réel permet de prendre des décisions plus rapidement et de réduire les arrêts imprévus.

Précision améliorée avec un pyromètre de référence

Les facteurs environnementaux et les conditions atmosphériques comme l’humidité ou les épisodes climatiques (brouillard, fortes pluies, neige, etc.) peuvent atténuer le signal des mesures infrarouges. KILNSCAN résout ce problème grâce à un pyromètre de référence optionnel installé près de la virole, qui vérifie les données du scanner et compense l’absorption atmosphérique.La comparaison continue entre les données du pyromètre et du scanner permet de maintenir une surveillance fiable 24/7, permettant un contrôle constant du processus et la protection des réfractaires.

Surveillance du stress mécanique - déformation thermique - et glissement de bandage

Les inhomogénéités thermiques sur la virole du four peuvent indiquer un stress structurel, souvent invisible jusqu’à ce que des dommages se produisent. La surveillance de la déformation thermique de KILNSCAN identifie ces zones de stress tôt en analysant les distorsions liées à la température, notamment autour des bandages.

Le système mesure également le glissement de bandage, même à des vitesses extrêmement faibles inférieures à 0,1 RPM. La surveillance de ce mouvement est particulièrement cruciale lors des d’arrêts et redémarrages, lorsque le stress sur la structure du four peut être à son maximum.

Intégration transparente et interface intuitive

KILNSCAN s’intègre à tout système de contrôle d’usine (PLC) et propose une interface complète avec superpositions graphiques, zones d’alarme personnalisées et enregistrement des données historiques. Le logiciel inclut également des fonctionnalités telles que :

- Comparaison de profils de référence

- Cartographie du briquetage

- Analyse zonale de la température

- Protocole OPC, sorties analogiques 4-20 mA et sorties numériques

Les opérateurs peuvent configurer jusqu’à 20 alarmes indépendantes basées sur des seuils max/min ou des variations de température, garantissant une réactivité en temps réel sur tout le four.

Besoin d’aide pour la surveillance thermique de votre four rotatif ?

Demandez votre solution personnalisée

Contrôle de la flamme et de la combustion internes avec PYROSCAN

Imagerie haute résolution pour une meilleure compréhension de la combustion

PYROSCAN est une caméra haute température avancée qui fournit des images thermiques et visibles du processus de combustion à l’intérieur du four. Il aide les opérateurs à surveiller la stabilité de la flamme, les températures du clinker et la performance des brûleurs en temps réel.

PYROSCAN capture une vue thermique dynamique de toute la zone de combustion. Cela inclut le suivi en temps réel de :

- La forme et la trajectoire de la flamme ( deviation de la flamme)

- La température de la flamme et la température de chute du clinker

- Le comportement du brûleur et les obstructions ou accumulations de chandelles sur la tuyère.

- Les zones de croûtage, l’anneau nasal et la chute dans le refroidisseur

Détection précoce des anomalies de combustion

Les fluctuations de la forme ou de la température de la flamme indiquent souvent des problèmes plus profonds dans le processus : variations de la qualité du combustible, mauvais réglages ou désalignement du brûleur, ou incohérences dans le flux d’air. PYROSCAN permet de détecter ces problèmes tôt, permettant aux équipes de maintenance d’intervenir avant qu’ils n’affectent la qualité du clinker ou n’endommagent les composants internes du four

Le système peut également détecter l’accumulation de « chandelles » sur les tuyères des brûleurs et l’usure des segments de l’anneau nasal, deux éléments qui, s’ils ne sont pas vérifiés, peuvent entraîner des problèmes mécaniques majeurs ou des pertes d’efficacité.

Optimisation de l'utilisation du combustible et soutien à la décarbonation

PYROSCAN permet aux opérateurs de régler finement les paramètres du brûleur et de l’air primaire pour garantir une combustion complète. Cela améliore l’efficacité thermique et aide à réduire la consommation spécifique de carburant. Pour les usines utilisant des combustibles alternatifs, la surveillance précise de la flamme est particulièrement importante pour éviter une combustion incomplète et mieux contrôler les émissions.

PYROSCAN est également utilisé dans les applications d’argile calcinée, où les températures de combustion sont plus basses que pour le clinker. La caméra peut être calibrée pour s’adapter à la température spécifique de calcination des argiles, ce qui en fait un outil précieux pour les essais de production de ciment à faible émission de carbone.

Intégration intelligente et fonctionnalités de numérisation

Conçu pour être compatible avec l’Industrie 4.0, PYROSCAN inclut des fonctionnalités logicielles compatibles avec l’IA et des options d’interface robustes telles que :

- Protocoles OPC (UA & DA)

- Sorties analogiques 4-20 mA

- Flux vidéo thermique et/ou visible en direct

- Configuration illimitée des zones et alarmes associées

Son interface flexible et son HMI intuitif permettent aux opérateurs de visualiser, enregistrer et exporter des données pour une analyse à long terme ou des systèmes de contrôle automatisés, y compris des logiciels de prédiction.

Surveillance complète du four au refroidisseur

Lorsque KILNSCAN et PYROSCAN sont associés, ils forment une solution complète couvrant à la fois la supervision thermique externe et interne du four rotatif. Cette combinaison permet une visibilité totale sur le fonctionnement du four :

- KILNSCAN assure l’intégrité de la coque, protège les réfractaires et détecte les points chauds.

- PYROSCAN offre un aperçu dynamique de la combustion, des performances des brûleurs et du lit de clinker.

De plus, PYROSCAN peut être installé dans le refroidisseur à clinker [lien vers la page web] pour surveiller les températures des grilles, détecter les formations de » chandelles » ou de « rivières rouges », et aider à réguler la vitesse des grilles ou le soufflage pour un refroidissement optimal.

Solution de surveillance thermique des fours rotatifs

Principaux avantages de la surveillance thermique du four rotatif

Améliorer la sécurité et prévenir les arrêts imprévus

La détection en temps réel des zones chaudes, de l'usure des réfractaires ou de l'instabilité de la flamme permet au personnel de l'usine de prendre des mesures correctives avant que des dommages ne surviennent, réduisant ainsi les risques pour les équipements et le personnel.

Augmenter la durée de vie des équipements et réduire les coûts de maintenance

En stabilisant les conditions thermiques et en détectant les signes précoces de défaillance, la surveillance infrarouge protège les revêtements des fours, les rouleaux, les paliers et les brûleurs, réduisant ainsi les arrêts coûteux et les remplacements de pièces.

Optimiser l'utilisation de l'énergie et réduire les émissions

Les données thermiques aident à affiner le processus de combustion et soutiennent la transition vers les combustibles alternatifs en garantissant une combustion complète et efficace, contribuant ainsi aux objectifs de réduction des émissions de CO₂.

Améliorer la qualité du clinker et la productivité

Des profils de température stables à l'intérieur et à l'extérieur du four conduisent à des conditions de de fabrication plus homogènes, de meilleures propriétés du clinker et moins de lots non conformes.

La surveillance thermique des fours rotatifs ne se fait plus simplement à des fins de sécurité, mais devient un élément clé d’une production de ciment efficace et durable. En fournissant des cartes thermiques en temps réel, des diagnostics avancés et une intégration totale avec les systèmes de contrôle d’usine, KILNSCAN et PYROSCAN permettent aux fabricants de ciment de réduire la consommation d’énergie, d’étendre la durée de vie des fours, d’optimiser la maintenance et d’assurer une qualité constante du clinker.

Que vous modernisiez une installation existante ou que vous construisiez une nouvelle usine, la mise en œuvre de la surveillance thermique en temps réel et de l’instrumentation thermographique est un pas vers une fabrication de ciment plus intelligente, plus sûre et plus compétitive !