PYROSCANCOOLED VISUAL AND PYROMETRIC CAMERA

Ideal for combustion zone and hot process applications : Rotary Kilns , Clinker Cooler , Reheating furnace, Boilers

PYROSCAN is a unique, high performance cooled megapixel visual and pyrometric camera designed to monitor combustion zones and more generally hot process areas.

The camera is connected to a computer and is associated with a specific software displaying a High Definition and High Dynamic Range (HDR) visual and thermal image of the combustion zone or hot area (visualization and temperature measurement of the flame, clinker or of any other material).

Each pixel of the image can be selected by the operator to read its temperature. In addition, specific shapes and lines can be defined in the image to monitor changes in flame shape, position of combustion area, product and wall temperatures, level of material, etc.

PYROSCANCOOLED VISUAL AND PYROMETRIC CAMERA

Ideal for combustion zone and hot process applications : Rotary Kilns , Clinker Cooler , Reheating furnace, Boilers

PYROSCAN is a unique, high performance cooled megapixel visual and pyrometric camera designed to monitor combustion zones and more generally hot process areas.

The camera is connected to a computer and is associated with a specific software displaying a High Definition and High Dynamic Range (HDR) visual and thermal image of the combustion zone or hot area (visualization and temperature measurement of the flame, clinker or of any other material).

Each pixel of the image can be selected by the operator to read its temperature. In addition, specific shapes and lines can be defined in the image to monitor changes in flame shape, position of combustion area, product and wall temperatures, level of material, etc.

MAIN BENEFITS

HIGH RESOLUTION: MEGAPIXEL SHARPNESS

1,280 x 960 measurement points in the image, 60 fps frame rate

HIGH DYNAMIC RANGE

Extended visualization & measurement range (600°C – 2000°C), details of under-exposed or saturated areas

VIDEO MANAGEMENT

Digital Zoom, Automatic / Manual control of camera settings, IR color-coding, Auto contrast enhancement

FoV AVAILABLE

62° (Hor.) × 48° (Vert.) / 78° (Diag.), 44° (Hor.) × 33° (Vert.) / 55° (Diag.), 80° (Hor.) × 65° (Vert.) / 90° (Diag.)

Pyroscan Software for Easy Control

The PYROSCAN software enables the operator to remotely control the extraction and the insertion of the PYROSCAN thermal camera into the kiln, and provides accurate temperature measurements and contrasted imagery in the firing zone. Multiple measurement areas can be defined and alarms can be set in those areas. The temperature of the zones can be stored into a database and reviewed for further analysis. The software also includes an OPC client option for sharing data on the plant network as well as video streaming over IP. Values from defined areas can also be continuously transmitted using 4-20mA outputs (up to 16 channels).

PYROSCAN software offers unlimited number of zones and free shape zones, as well as live graphs display. Each zone can be associated to an alarm based on minimum, maximum or average temperature ranges.

With both images – Visible and Thermal – available simultaneously, much more details can be revealed by a single equipment.

Pyroscan Software for Easy Control

The PYROSCAN software enables the operator to remotely control the extraction and the insertion of the PYROSCAN thermal camera into the kiln, and provides accurate temperature measurements and contrasted imagery in the firing zone. Multiple measurement areas can be defined and alarms can be set in those areas. The temperature of the zones can be stored into a database and reviewed for further analysis. The software also includes an OPC client option for sharing data on the plant network as well as video streaming over IP. Values from defined areas can also be continuously transmitted using 4-20mA outputs (up to 16 channels).

PYROSCAN software offers unlimited number of zones and free shape zones, as well as live graphs display. Each zone can be associated to an alarm based on minimum, maximum or average temperature ranges.

With both images – Visible and Thermal – available simultaneously, much more details can be revealed by a single equipment.

FEATURES

PYROSCANFEATURES

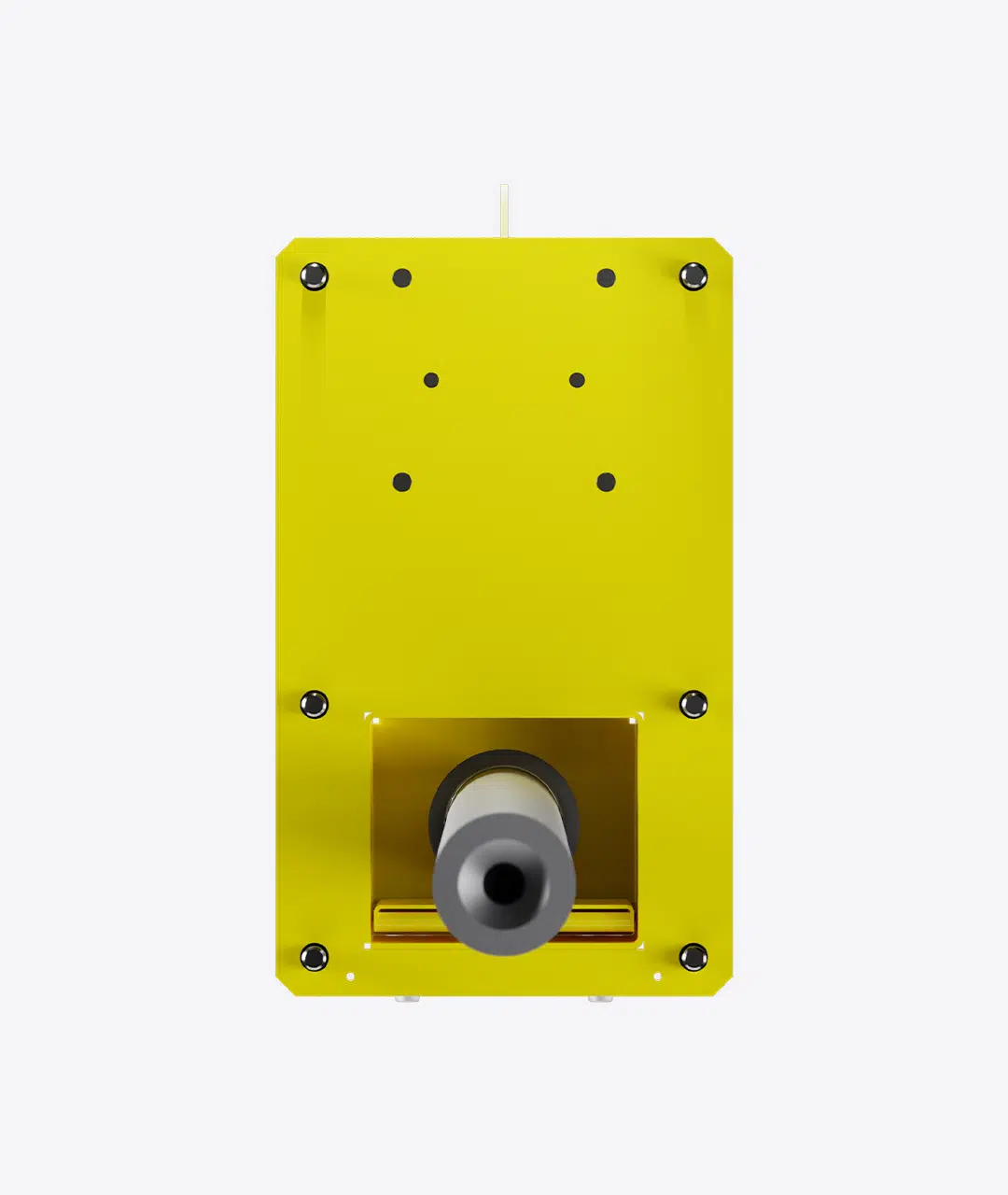

A water cooler pyrometric camera

An air treatment unit

A local electrical control cabinet

A PC with dedicated software under Windows environment for data processing and display

Combustion Zone and Hot Process Applications

The thermal camera PYROSCAN is particularly well suited to kilns, clinker grate coolers, combustion chambers, incineration furnaces, heaters and boilers since it enables accurate temperature monitoring, detection of any changes due to burner or process adjustment, raw meal and fuel composition variation…

It combines visible and thermal images with temperatures from 600°C to 2000°C.

The cooled PYROSCAN thermal camera is mounted on a pneumatic actuator controlled by a local electrical cabinet enabling insertion or retraction of the camera. A local air processing unit cabinet supplies the camera with compressed air for dust removal on the front window and feeds the pneumatic actuator chambers.

Combustion Zone and Hot Process Applications

The thermal camera PYROSCAN is particularly well suited to kilns, clinker grate coolers, combustion chambers, incineration furnaces, heaters and boilers since it enables accurate temperature monitoring, detection of any changes due to burner or process adjustment, raw meal and fuel composition variation…

It combines visible and thermal images with temperatures from 600°C to 2000°C.

The cooled PYROSCAN thermal camera is mounted on a pneumatic actuator controlled by a local electrical cabinet enabling insertion or retraction of the camera. A local air processing unit cabinet supplies the camera with compressed air for dust removal on the front window and feeds the pneumatic actuator chambers.

PYROSCANFIXED COOLED VISUAL AND PYROMETRIC CAMERA

Ideal for applications : Waste-to-Energy , Steel EAF / BOF

The cooled PYROSCAN-F thermal camera is fixed on the combustion chamber wall with a dedicated flange for easy dismantling and repositioning. Its Electrical panel fitted with a local PLC allows the operator to receive alarms in case of low water flow, low compressed air, or high temperature at the camera probe.

Endoscope available in :

- SS316 or Hastelloy ( corrosion resistant for hazardous waste incineration for instance )

- 500 or 1000mm length

PYROSCAN-UCOMPACT VISUAL AND PYROMETRIC CAMERA

Flame front visualization and temperature monitoring for application Waste-to Energy and Steel plants

The PYROSCAN-U thermal camera includes the following sub-assemblies:

- visual / thermography camera head,

- local electrical control cabinet,

- system for data acquisition, processing and display.

Additional modules are provided to support options selected by the Client.

PYROSCAN-UCOMPACT VISUAL AND PYROMETRIC CAMERA

Flame front visualization and temperature monitoring for application Waste-to Energy and Steel plants

The PYROSCAN-U thermal camera includes the following sub-assemblies:

- visual / thermography camera head,

- local electrical control cabinet,

- system for data acquisition, processing and display.

Additional modules are provided to support options selected by the Client.

PYROSCAN-UMAIN BENEFITS

USER-FRIENDLY AND CUSTOMIZABLE SOFTWARE

Seamlessly integrates into your Plant Control System

EASY SET UP – NO EXTERNAL COOLING UNIT REQUIRED

Quick installation, no extra infrastructure needed

COMPACT, EASY-TO-INTEGRATE, LIGHTWEIGHT, COST-EFFECTIVE

Minimal footprint for easy furnace-side deployment

MAINTENANCE IS REDUCED TO A MINIMUM

Reliable system with no calibration or upkeep required

Compact and User-Friendly Solution

Pyroscan-U high performance sensor is housed in a compact, IP66 resistant box, complemented by a small size electronic IP66 cabinet and a remote computer with optional printer. Since the thermal camera is designed to withstand the environment in the immediate vicinity of the furnace, no additional cooling element is necessary and the installation infrastructure is kept to a minimum. The software is designed to send all the information through the OPC client or through eight 4-20 mA outputs, thus allowing easy integration into the Plant Control System (PCS). Pyroscan-U requires minimal installation time and wiring; relying mainly on Ethernet or fiber optic connections, the system can be set up in a few hours’ time to provide consistent and reliable monitoring over its lifetime. With no calibration or maintenance needed the system cuts down on maintenance and other costs.

Compact and User-Friendly Solution

Pyroscan-U high performance sensor is housed in a compact, IP66 resistant box, complemented by a small size electronic IP66 cabinet and a remote computer with optional printer. Since the thermal camera is designed to withstand the environment in the immediate vicinity of the furnace, no additional cooling element is necessary and the installation infrastructure is kept to a minimum. The software is designed to send all the information through the OPC client or through eight 4-20 mA outputs, thus allowing easy integration into the Plant Control System (PCS). Pyroscan-U requires minimal installation time and wiring; relying mainly on Ethernet or fiber optic connections, the system can be set up in a few hours’ time to provide consistent and reliable monitoring over its lifetime. With no calibration or maintenance needed the system cuts down on maintenance and other costs.

PYROSCAN-UFEATURES

PYROSCAN-UFEATURES

HIGH RESOLUTION

Of 1,280 x 960 px frame rate reaches 60 fps

FIELD OF VIEW

62° H x 48° V / 78° D, on request : 44° H x 33° V / 55°D

CAMERA OUTPUT

Gigabit Ethernet (GigE Vision compliant)

TEMPERATURE MEASUREMENT RANGE:

Adjusted within the 500°C – 1,850 C range. The ambient temperature around the camera head should not exceed 50* C