Visible, UV & SWIR Imager characterization

Visible, UV & SWIR Imager characterization

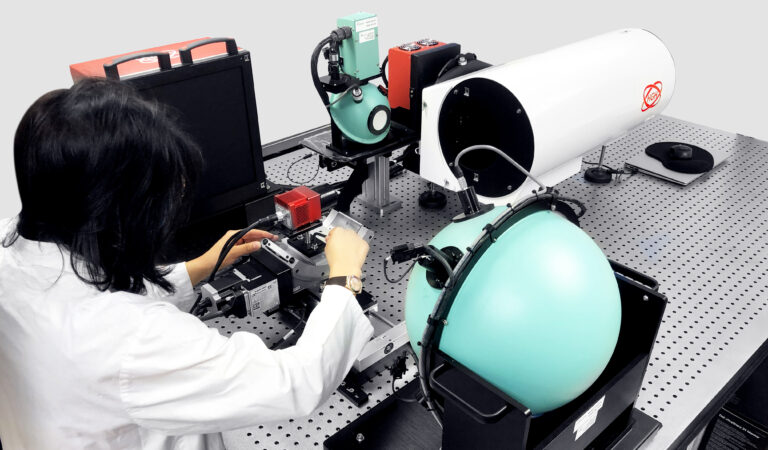

HGH provides top-of-the-line equipment perfect for assessing UV, Visible and SWIR optical systems, ensuring the best reliability with each use. Our equipment is specifically designed to meet a range of different needs for end-users in diverse industries:

Precision Optical System Assessment

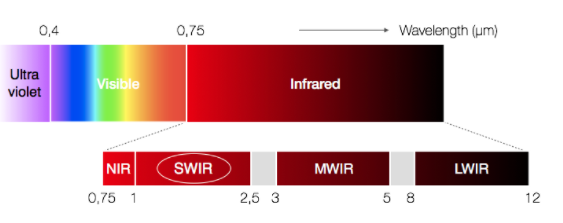

- A range of Integrating Sphere reference sources providing a highly stabilized, uniform and wide level-range luminance from 200 to 2500nm.

- A range of standard targets, with the various patterns and sizes required to perform standard measurements. HGH can also supply any type of pattern to meet specific needs.

- A range of off-axis collimators, to project the test image of a target in front of a integrating sphere

- Infratest: Your Turnkey Electro-Optical test Software

Imager Characterization: Which Parameters are Tested?

The process of imager characterization involves a meticulous examination of a multitude of parameters, enabling users to conduct a comprehensive evaluation of the performance of either Visible cameras or UV/SWIR devices. These parameters encompass a wide array of factors, offering a holistic view of the device’s capabilities. While we’ve mentioned some of these parameters, it’s important to note that the list is far from exhaustive. Here, we delve deeper into the parameters that constitute this rigorous assessment:

Minimum Resolvable Contrast (MRC): This critical parameter assesses the system’s ability to distinguish between objects with varying levels of contrast, an essential aspect in scenarios where visibility is challenged.

Fixed Pattern & Temporal Noise: Understanding and mitigating noise, both fixed pattern and temporal, is crucial for obtaining clear and accurate images. These types of noise can significantly impact image quality and are thus essential considerations.

Modulation Transfer Function (MTF): MTF measures the system’s ability to faithfully reproduce the fine details of an image. It helps in gauging how well the imager can capture the nuances of a scene.

Spatial Resolution: Spatial resolution determines the level of detail that can be resolved in an image. A higher spatial resolution implies the ability to distinguish finer features, which can be invaluable in applications requiring precise imaging.

Field of View (FOV): FOV defines the extent of the scene that the imager can capture. It’s a fundamental parameter, especially in applications where a wide field of view is required to monitor or analyze large areas.

Distortion: Distortion correction is vital for ensuring that images accurately represent the scene. Correcting for distortion can be essential in applications like image stitching or photogrammetry.

Optical Axis Alignment: Precise optical alignment ensures that the imager’s optical components work harmoniously, resulting in clear and accurate images. Misalignment can lead to image degradation.

Dynamic Range: Dynamic range measures the ability of the imager to capture a wide range of light intensities, from the darkest shadows to the brightest highlights. A higher dynamic range is advantageous in situations with varying lighting conditions.

Saturation Level: Understanding the saturation level is crucial to prevent overexposure in high-intensity lighting conditions, ensuring that no critical image information is lost.

This comprehensive list highlights the myriad aspects that can be meticulously analyzed during the imager characterization process. These parameters collectively provide an unparalleled level of insight into the functionality and capabilities of the aforementioned devices. By enabling such a thorough evaluation process, users can confidently assess the suitability of cameras and devices for specific tasks, making imager characterization an invaluable tool across a wide spectrum of industries and applications. Whether it’s for surveillance, scientific imaging, or industrial quality control, this rigorous assessment process ensures that imaging devices meet the exacting standards of their intended use cases, ultimately contributing to enhanced performance and reliability.

Imager Characterization Services

In addition to the meticulous evaluation of optical parameters mentioned above, HGH also provides robust testing protocols and expert guidance to ensure that your imaging systems meet the highest industry standards. Our experienced team of engineers and technicians is dedicated to assisting you in every step of the characterization process. Whether you are in research and development, quality control, or manufacturing, our goal is to empower you with precise insights into your optical systems’ performance. With HGH’s cutting-edge equipment and comprehensive testing procedures, you can have confidence in the reliability and efficiency of your cameras and devices across various applications and industries.