Blackbody targets

Blackbody Targets for Infrared and Visible tests

Blackbody Target: Various pattern and size for characterization of visible and infrared optronic systems

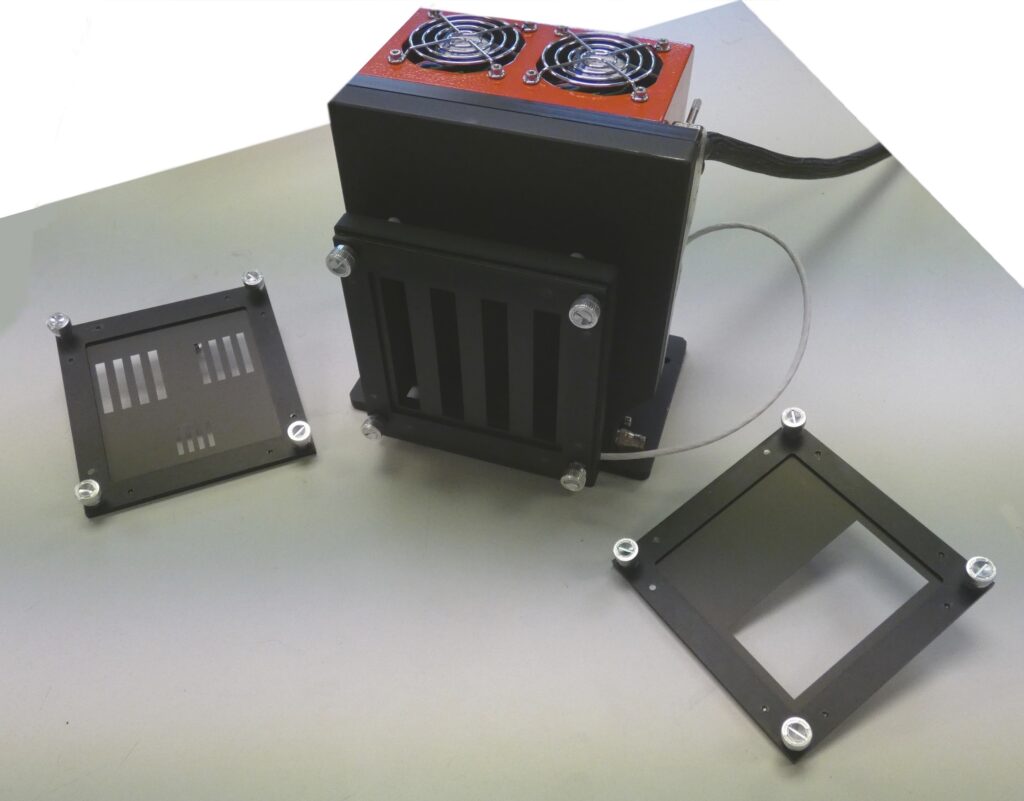

HGH’s blackbody targets are strategically adapted to your specific testing environments and protocols, able to be seamlessly integrated either through mounting onto a collimator target wheel or directly affixing onto the forefront of a blackbody or a visible source. The incorporation of a high-accuracy sensor enables the real-time measurement and monitoring of the target temperature, ensuring a robust and consistent thermal reference throughout the evaluation process.

Blackbody Target patterns and dimensions are meticulously designed, taking into account the unique variables of the test being conducted and the intrinsic characteristics of the camera or sensor system being evaluated. Ensuring that each target is not only compliant with testing standards but is also finely tuned to the particularities of each system and testing protocol, is paramount.B

HGH's Blackbody Targets advantages

Our blackbody targets are strategically adapted to your specific testing environments and protocols, able to be seamlessly integrated either through mounting onto a collimator target wheel or directly affixing onto the forefront of a blackbody or a visible source. The incorporation of a high-accuracy sensor enables the real-time measurement and monitoring of the target temperature, ensuring a robust and consistent thermal reference throughout the evaluation process.

Blackbody target patterns and dimensions are meticulously designed, taking into account the unique variables of the test being conducted and the intrinsic characteristics of the camera or sensor system being evaluated. HGH ensures that each target is compliant with testing standards but also finely tuned to the particularities of each system and testing protocol.

TARGETS

Blackbody: Most frequently used patterns

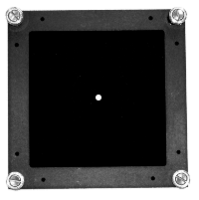

Harmonization target (pinhole) for optical axis alignment of the UUT optronic system.

Harmonization target (pinhole) for optical axis alignment of the UUT (Unit Under Test) optronic system is paramount for ensuring the precision and accuracy of optical alignment throughout the device’s operational framework. Employing a pinhole target facilitates the harmonization of various optronic channels, ensuring co-alignment and optimizing system performance across diverse operational conditions and mission profiles.

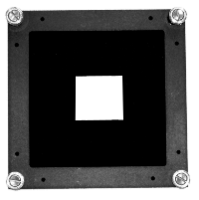

Square target for field of view measurement

The square target, utilized for field of view (FOV) measurement, plays a pivotal role in calibrating and verifying the angular field of view of optronic devices to ascertain the optical system’s accuracy in capturing and analyzing spatially distributed light. Precision in FOV measurements is crucial, as it directly influences the device’s ability to accurately represent and analyze the observed scene, thus ensuring fidelity between the measured and actual spatial characteristics of the environment.

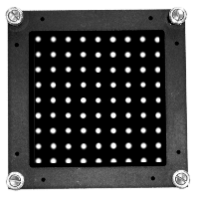

Distortion target for distortion image measurement

The distortion target for distortion image measurement is instrumental in assessing and calibrating the optical aberrations and imperfections present in the imaging system. It serves to identify, quantify, and potentially correct anomalies like barrel or pincushion distortions in the optics of the Unit Under Test (UUT), ensuring that the system provides accurate and true-to-source imagery across its entire field of view, thereby validating the integrity and reliability of the imaging system’s output.

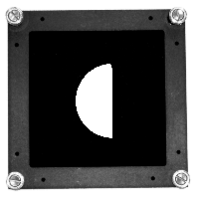

Knife-edge target for Modulation Transfer Function calculation (MTF)

A knife-edge target for Modulation Transfer Function (MTF) calculation is paramount in optoelectronic testing, providing a high-contrast edge that facilitates the assessment of an imaging system’s spatial frequency response. Utilizing a knife-edge target allows analysts to discern the ability of an optical system to preserve the contrast of sinusoidal patterns at varying spatial frequencies, which is pivotal to characterizing the system’s resolving power and overall imaging performance.

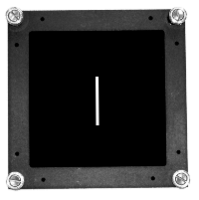

Slit target for Line Spread Function calculation (LSF)

Utilizing a slit target for Line Spread Function (LSF) calculation is fundamental in evaluating the spatial resolution and imaging performance of optical and electro-optical systems. The slit target provides a high-contrast vertical transition which is instrumental in determining how an imaging system responds to a spatial impulse, allowing technicians and engineers to precisely assess and quantify the system’s resolution and the sharpness of its imaging capabilities.

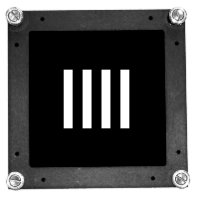

4-bar target for thermal resolution measurement of infrared camera (MRTD: Minimum Resolvable Temperature Difference)

The 4-bar target, essential for thermal resolution measurement, particularly in relation to Minimum Resolvable Temperature Difference (MRTD) of infrared cameras, enables a precise evaluation of the camera’s ability to resolve closely spaced thermal gradients. Through strategic alignment and variation of the bars, it challenges the camera’s thermal and spatial resolution, thereby providing a robust metric to evaluate the thermal performance and discernment capability of the infrared camera under various conditions.

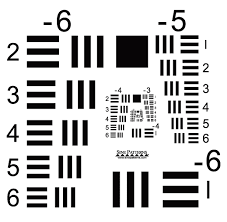

Visible Target USAF1951

The Visible Target USAF1951, widely used for resolving power determination in optical systems, encompasses a series of elements composed of three horizontal and three vertical bars, varying systematically in size to challenge and assess the system’s spatial resolution capabilities. Its structure enables a standardized measurement of an optical system’s modulation transfer function, thereby offering a benchmark for analyzing and comparing the resolving power of imaging systems, ensuring they adhere to requisite performance standards in visible light applications.